"scoob" (scoobsti)

"scoob" (scoobsti)

02/26/2014 at 18:29 • Filed to: Ghostride the Blip

2

2

4

4

"scoob" (scoobsti)

"scoob" (scoobsti)

02/26/2014 at 18:29 • Filed to: Ghostride the Blip |  2 2

|  4 4 |

I haven't got a damn clue what anything means in that camless engine article. /KnowledgableSoCalledGearhead

Tom McParland

> scoob

Tom McParland

> scoob

02/26/2014 at 18:31 |

|

Don't feel bad I didn't even read it because I couldn't get past ZOMG manual SAAB wagon!

Your boy, BJR

> scoob

Your boy, BJR

> scoob

02/26/2014 at 18:34 |

|

I just shared it to my dad's FB because he's a major Saabhead and let him work it out.

Brian, The Life of

> Tom McParland

Brian, The Life of

> Tom McParland

02/26/2014 at 18:41 |

|

I'm just enjoying the notion of a modern (momentarily) 2-stroke SAAB! ;)

You can tell a Finn but you can't tell him much

> scoob

You can tell a Finn but you can't tell him much

> scoob

02/27/2014 at 13:24 |

|

That is a pretty interesting article on the Koenigsegg camless engine, but it is hard to visualize without pictures. Here is a GIF showing a pushrod V-twin link because borked . The camshaft spins around and a follower rides on it. The follower (multi colors) pushes on the pushrod (light yellow) which pushes a rocker arm (red) which pushes on the valve stem (green) opening the valve. The valve spring pushes back against everything and closes the valve when the cam profile allows for it.

If you look at the valve opening v. time it will look something like this picture.

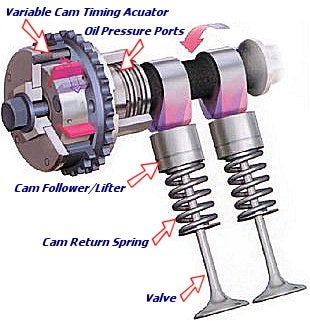

The problem with a camshaft is that it doesn't let you do a whole lot with the valves. Depending on engine speed and load you want different amounts of valve overlap (how long both valves are open), different amounts of valve lift (how far the valve opens) and when the valves open with regards to TDC. Most modern engines do have variable valve timing , but it is pretty limited. Basically they adjust either the exhaust or intake cam timing by slightly changing the angle of the cam relative to the crank. They do this by using oil pressure to adjust the angle between the cam sprocket and the camshaft. This allows for adjustment of cam timing, but not duration or lift which is determined by the cam profile.

Even with variable valve timing you can't really do much to the cam profile since it is literally ground into the steel of the camshaft. You can have multiple cam profiles like VTEC, but that gets pretty complicated to actuate and doesn't help things in the middle. Basically you have a low rpm cam and a high rpm cam, but you miss out on the mid range.

FIAT's Multi-air system goes a little bit farther by using hydraulics to modify the lift and duration of the intake cam. Basically the follower can change its length and is controlled by oil pressure and volume. This gives better control of things over a wider range of operating conditions.

What Koenigsegg has done is get rid of the camshaft, followers, pushrods, rocker arms and coil spring on the valve. They replaced that with a pneumatic actuator that they control to open and close the valve. That allows them to get the valves open and closed much quicker than a camshaft does. It also allows infinitely variable valve timing and a whole lot of other stuff. Since they aren't trying to keep a bunch of mechanical bits following the profile of a cam they can pretty much go from fully closed to fully open which gives the "square cam profile" that they are talking about. If you looked at valve position versus time for their engine it would look pretty close to this picture.

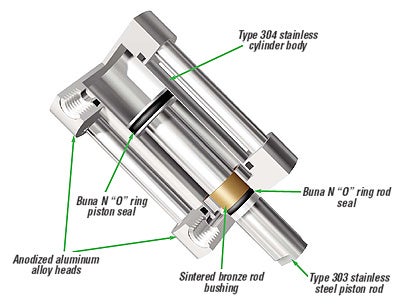

Since each valve has its own actuator and each actuator is controlled independently they are able to accomplish all sorts of neat control stuff. Valve lift, timing, and duration are all controlled for each valve individually so you also have complete control over valve overlap. I am making the assumption that they are using a double acting pneumatic actuators. These would have air inputs on both ends and you control it by pumping air into one end or the other. These are very common in industrial settings for moving parts around and actuating machinery. Obviously an automotive valve application would be miniaturized but it would still be pretty similar to this picture.

Possibly they are using a single acting cylinder which would have a mechanical return spring and only require compressed air input to one side. That would be something like this.