"Chris_K_F drives an FR-Slow" (chriskf)

"Chris_K_F drives an FR-Slow" (chriskf)

12/04/2014 at 14:51 • Filed to: None

0

0

9

9

"Chris_K_F drives an FR-Slow" (chriskf)

"Chris_K_F drives an FR-Slow" (chriskf)

12/04/2014 at 14:51 • Filed to: None |  0 0

|  9 9 |

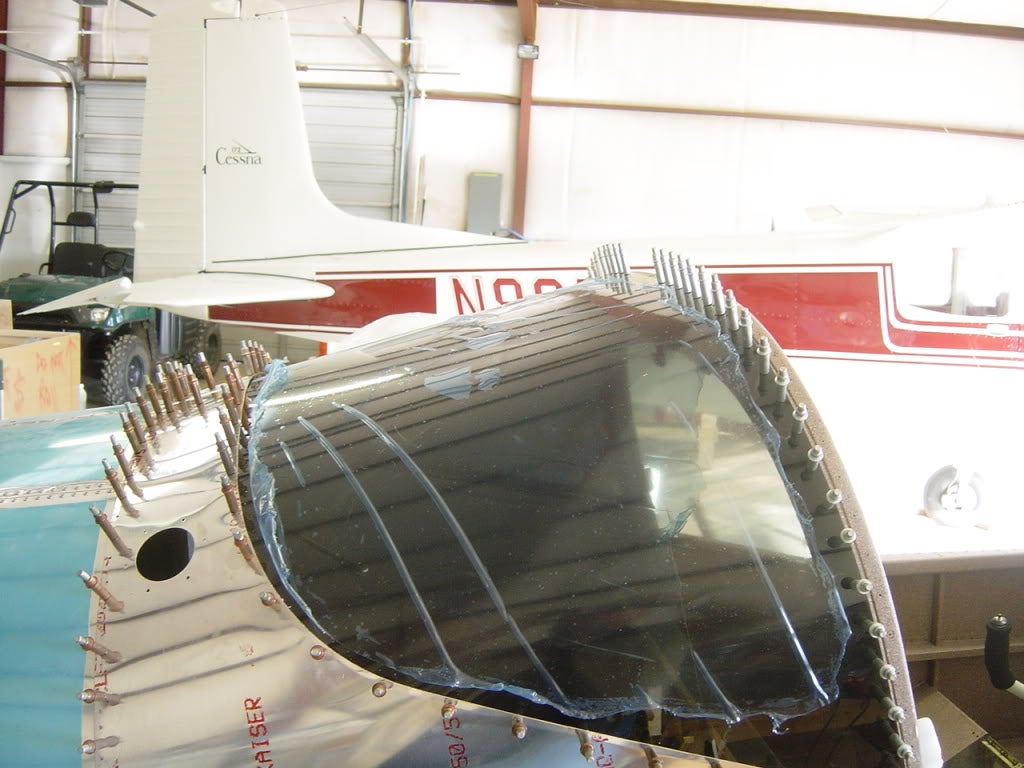

forming plexiglass.

I am currently involved in an awesome budget automotive project (can't divulge too may details at this point, but there will be a lengthy write up when the project is completed). We're at a point in the project where we'd like to form a bubble-like rear window. The main option we've come up with is plexiglass, but this would require us acquiring a cheap used electric oven; since plexiglass has to be baked at 250-350 degrees for 20-30 minutes. While we could do this, it would certainly prove challenging, and potentially costly.

Do any of you have experience working with plexiglass and can offer some advice, or suggestions of possible alternative methods/materials?

RamblinRover Luxury-Yacht

> Chris_K_F drives an FR-Slow

RamblinRover Luxury-Yacht

> Chris_K_F drives an FR-Slow

12/04/2014 at 14:55 |

|

No, I think Plexiglass is your best option, probably. You may need to build a wood frame big enough to enclose what you have and make a metal skin to hold it in, and buy two or more ovens for the thermostat and heating element. Unless it's small enough to fit in a truck toolbox, and not an oven. If it's small enough to go in a truck toolbox, you can rig the thermostats and heating elements into that.

Sam

> Chris_K_F drives an FR-Slow

Sam

> Chris_K_F drives an FR-Slow

12/04/2014 at 14:57 |

|

Lexan. You can use a heat gun to form it. You'll have to make a mold first to heat it over, but that's cheaper than an oven.

Chris_K_F drives an FR-Slow

> RamblinRover Luxury-Yacht

Chris_K_F drives an FR-Slow

> RamblinRover Luxury-Yacht

12/04/2014 at 15:04 |

|

I assumed as much. It won't be small enough for a truck tool box. We have some time to get this done, so the metal enclosure will probably be the best way to go.

Chris_K_F drives an FR-Slow

> Sam

Chris_K_F drives an FR-Slow

> Sam

12/04/2014 at 15:05 |

|

That sounds like it could definitely be a better option. I'll have to look into that and bring it up with the other guys on the build.

Mattbob

> Chris_K_F drives an FR-Slow

Mattbob

> Chris_K_F drives an FR-Slow

12/04/2014 at 15:06 |

|

dont use plexi, use lexan (search for polycarbonate sheets) , its a lot less prone to cracking and shattering.

Chris_K_F drives an FR-Slow

> Mattbob

Chris_K_F drives an FR-Slow

> Mattbob

12/04/2014 at 15:08 |

|

This bubble window will only be used for aesthetic purposes, and removed for any real drive time.

Mattbob

> Chris_K_F drives an FR-Slow

Mattbob

> Chris_K_F drives an FR-Slow

12/04/2014 at 15:10 |

|

Just for ease of forming, let alone durability. Polycarb is a lot less prone to crack when you are trying to form it. Its not super expensive if you get generic stuff.

Chris_K_F drives an FR-Slow

> Mattbob

Chris_K_F drives an FR-Slow

> Mattbob

12/04/2014 at 15:16 |

|

Correction, looking back at the latest email from the main builder on the car lexan is what we're planning on using. Apparently he just found an electric oven for $30 on Craigslist too. haha

Phyrxes once again has a wagon!

> Chris_K_F drives an FR-Slow

Phyrxes once again has a wagon!

> Chris_K_F drives an FR-Slow

12/04/2014 at 15:25 |

|

Drop forming it is the way to go, but the issue you will have with an cheap oven is how even the heat is distributed. But without spending real money on to do this an oven is potentially your best bet. Depending on your set up it may be easier to just heat the sheet in the oven and take it out and clamp it to the form (while hot) and let it cool on the form. This is not terribly different than the heatgun and clamp method.