"roflcopter" (roflroflroflcopter)

"roflcopter" (roflroflroflcopter)

11/11/2014 at 00:26 • Filed to: None

5

5

33

33

"roflcopter" (roflroflroflcopter)

"roflcopter" (roflroflroflcopter)

11/11/2014 at 00:26 • Filed to: None |  5 5

|  33 33 |

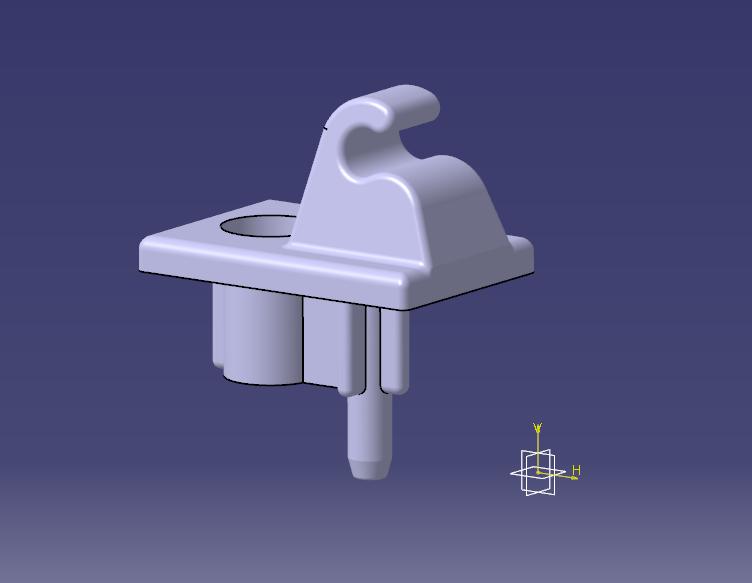

Well, made the model of it at least. Hopefully I'll get a chance to try and print it before the week is over with.

It's the sunvisor clip out of my '85 Volvo 240, I had one that fell out in pieces and the other has been MIA since the beginning, hopefully I can get these to print alright and stop having floppy visors!

roflcopter

> roflcopter

roflcopter

> roflcopter

11/11/2014 at 00:27 |

|

Here's the broken remains I was working with, I'm pretty proud of myself.

Big Bubba Ray

> roflcopter

Big Bubba Ray

> roflcopter

11/11/2014 at 00:27 |

|

Thats awesome!

roflcopter

> Big Bubba Ray

roflcopter

> Big Bubba Ray

11/11/2014 at 00:32 |

|

I keep forgetting that my school has a 3D printer that they let students run whatever they want on for absurdly cheap... I need to take more advantage of it.

I also need to keep brushed up on my modeling skills... if anyone has anything they need whipped up I can try to find some time!

Steve in Manhattan

> roflcopter

Steve in Manhattan

> roflcopter

11/11/2014 at 00:33 |

|

Nice work - Volvo should hire you.

TheHondaBro

> roflcopter

TheHondaBro

> roflcopter

11/11/2014 at 00:35 |

|

You think you can whip me up a PC that can run Inventor? :P

roflcopter

> Steve in Manhattan

roflcopter

> Steve in Manhattan

11/11/2014 at 00:37 |

|

Lulz, I would actually be pretty alright with working for Volvo...

roflcopter

> TheHondaBro

roflcopter

> TheHondaBro

11/11/2014 at 00:38 |

|

Well, the PC I'm doing all of this on is hardcore last-gen shit. Core2duo, 4GB ram, half decent GPU though. I'm sure whatever you're rocking can handle some of it if this thing can handle what I throw at it. (I'll give you a hint, this ain't no Inventor I'm running.)

TheHondaBro

> roflcopter

TheHondaBro

> roflcopter

11/11/2014 at 00:40 |

|

Well what program are you running? Because I have a Mac.

roflcopter

> TheHondaBro

roflcopter

> TheHondaBro

11/11/2014 at 00:42 |

|

Yeah... I don't know what I would run if I were on my Mac...

I've been doing all of my modelling in Catia as of late(shhhh, don't tell anyone)

Distraxi's idea of perfection is a Jagroen

> roflcopter

Distraxi's idea of perfection is a Jagroen

> roflcopter

11/11/2014 at 00:43 |

|

Make sure you orient the build correctly, that clip is going to break quite nicely if you FDM it the way up it's shown in the image.

roflcopter

> Distraxi's idea of perfection is a Jagroen

roflcopter

> Distraxi's idea of perfection is a Jagroen

11/11/2014 at 00:48 |

|

I'm aware of that, I simply modeled it in the way you would usually look at it. I was actually going to try and print it laying on its 'back', with the opening of the c part of the clip facing upwards, but at a 45. I figure that will keep my layers in a direction that it shouldn't cause an issue and will also minimize the amount of support I need to work into the print.

Distraxi's idea of perfection is a Jagroen

> roflcopter

Distraxi's idea of perfection is a Jagroen

> roflcopter

11/11/2014 at 00:58 |

|

Probably as good an orientation as you're going to get. Clips are a pig with layering type 3D printers, it's almos impossible to avoid a weak spot. Roll on out-of-patent SLS!

roflcopter

> Distraxi's idea of perfection is a Jagroen

roflcopter

> Distraxi's idea of perfection is a Jagroen

11/11/2014 at 01:03 |

|

I ran into that issue with some headlight bushings for my buddy's RX7, broke a ton of them before I figured out the 'right' way to get them to print. My school has a MakerBot Replicator2, which definitely isn't bad, but sometimes I beat my head against the wall with its limitations.

NotUnlessRoundIsFunny

> roflcopter

NotUnlessRoundIsFunny

> roflcopter

11/11/2014 at 01:39 |

|

I cannot even begin to express how awesome this is!

Kailand09

> TheHondaBro

Kailand09

> TheHondaBro

11/11/2014 at 06:15 |

|

Autodesk Fusion 360 is your friend.

I Do It For Miatas, NC Owner

> roflcopter

I Do It For Miatas, NC Owner

> roflcopter

11/11/2014 at 07:34 |

|

So did you 3D scan the passenger side clip or did you make the model in CAD?

DancesWithRotors - Driving Insightfully

> Big Bubba Ray

DancesWithRotors - Driving Insightfully

> Big Bubba Ray

11/11/2014 at 08:03 |

|

Next, print a map pocket and one of the little trim rings that go around the door handles... If your 240 is anything like my old one, those are broken, too.

roflcopter

> I Do It For Miatas, NC Owner

roflcopter

> I Do It For Miatas, NC Owner

11/11/2014 at 08:58 |

|

I built a model from measurements I took of the broken one.

roflcopter

> DancesWithRotors - Driving Insightfully

roflcopter

> DancesWithRotors - Driving Insightfully

11/11/2014 at 08:58 |

|

My map pockets are mostly intact, and the door trims are actually all there. Surprising, I know.

itschrome

> roflcopter

itschrome

> roflcopter

11/11/2014 at 08:59 |

|

OH man I have so many clips and shit I could use printed.. you should start a compnay doing this! cause I can't fucking find the ones I need!

roflcopter

> itschrome

roflcopter

> itschrome

11/11/2014 at 09:02 |

|

Haha you wouldn't want to pay for my time to do it, that's why I was offering to hook some people up in my spare time. That model up there took about 2 hours to get right, so fi I were charging time + materials it would probably be a $30+ clip.

itschrome

> roflcopter

itschrome

> roflcopter

11/11/2014 at 09:04 |

|

I would gladly pay 30 a piece! I can't find what I need! it's aggravating!

luvMeSome142 & some Lincoln!

> roflcopter

luvMeSome142 & some Lincoln!

> roflcopter

11/11/2014 at 09:04 |

|

Very good job!

Big Bubba Ray

> DancesWithRotors - Driving Insightfully

Big Bubba Ray

> DancesWithRotors - Driving Insightfully

11/11/2014 at 09:40 |

|

They're both, surprisingly, intact!

DancesWithRotors - Driving Insightfully

> roflcopter

DancesWithRotors - Driving Insightfully

> roflcopter

11/11/2014 at 09:59 |

|

It (rarely) happens... I was shocked that my 740's map pockets didn't even have any cracks.. (They still don't, because I am extra careful, and I threaten death on anyone who breaks one...)

uofime

> roflcopter

uofime

> roflcopter

11/11/2014 at 10:13 |

|

you're not going to be able to print that unless you have a printer that can use support material.

what you can do is make the clip portion and base portion 2 different pieces print the clip on its side and the base upside down and glue them together.

I would normally suggest some alignment tabs for the bonding but they would have to be overhanging features and probably wouldn't work

roflcopter

> uofime

roflcopter

> uofime

11/11/2014 at 12:57 |

|

If memory is serving me correct the printer can create supports for overhanging stuff, I'm gonna give it a go as it is and see if I can make it work. My other thought was just to print a support structure, lay a piece of tape over it and then print this on that.

uofime

> roflcopter

uofime

> roflcopter

11/11/2014 at 14:56 |

|

so you mean printing it in the current orientation the supports being on that bottom plate?

I would suggest beefing up the back side of the clip since even if you do make is successfully the low layer to layer strength of FDM means the clip could snap in half where the visor goes in a lot more easily than the molded version would

roflcopter

> uofime

roflcopter

> uofime

11/11/2014 at 16:48 |

|

Ideally I'd print the clip portion with it laying on its side, but I can't quite figure out how to manage that without lots of supports either... we'll see what my buddy who runs the thing daily thinks is the best bet.

uofime

> roflcopter

uofime

> roflcopter

11/11/2014 at 16:52 |

|

is there a reason the clip part cannot be the full width of the part? if there's room on the visor for a longer clip extending it would make it easy to build in it's side.

roflcopter

> uofime

roflcopter

> uofime

11/11/2014 at 16:57 |

|

I'll have to go measure and see how much I can get away with. I was trying to avoid making things square and ugly though by following the existing design, but as this car has proven time and time again, 30 year old Swedish engineering is not always the best.

uofime

> roflcopter

uofime

> roflcopter

11/11/2014 at 17:21 |

|

yeah, don't limit your design to copying what they did, they had a different set of manufacturing limitations than you do

roflcopter

> uofime

roflcopter

> uofime

11/11/2014 at 17:42 |

|

Very good point. At least I now have a model with the import parts in all the right places, so I shouldn't have an issue replicating the screw holes, alignment peg, and clip spacing.