"bwp240" (bwp240)

"bwp240" (bwp240)

10/25/2014 at 14:05 • Filed to: Thought Experiments, Hypothetical Projects, Craigslist

1

1

1

1

"bwp240" (bwp240)

"bwp240" (bwp240)

10/25/2014 at 14:05 • Filed to: Thought Experiments, Hypothetical Projects, Craigslist |  1 1

|  1 1 |

You may recall how I tried to !!!error: Indecipherable SUB-paragraph formatting!!! . Many people probably read that and thought it was stupid. Oh do I have another fun hypothetical project for you (same disclaimers apply).

While cruising through Craigslist waiting for a program to compile, !!!error: Indecipherable SUB-paragraph formatting!!! . It's somebody's project Daytona which they decided that the engine and transmission were stupid so they got rid of them.

!!! UNKNOWN CONTENT TYPE !!!

Because the car is missing that pesky engine, an engine swap is quite easy now. Now most people would put in a Hellcat engine and convert the car to rear wheel drive and call it the greatest piece of motoring. I, however, propose taking it one step further, TURBINE POWER. Why, because most any liquid that can be combusted will work as fuel.

Sure it is not 707hp of internal combustion awesomeness, but it is significantly better than what was in there, hence why that part is gone. So first we need to figure out how big of an engine we can place into the car. We don't want to do too much fabrication work because we want to put in enough effort to put in a jet engine, but nothing more.

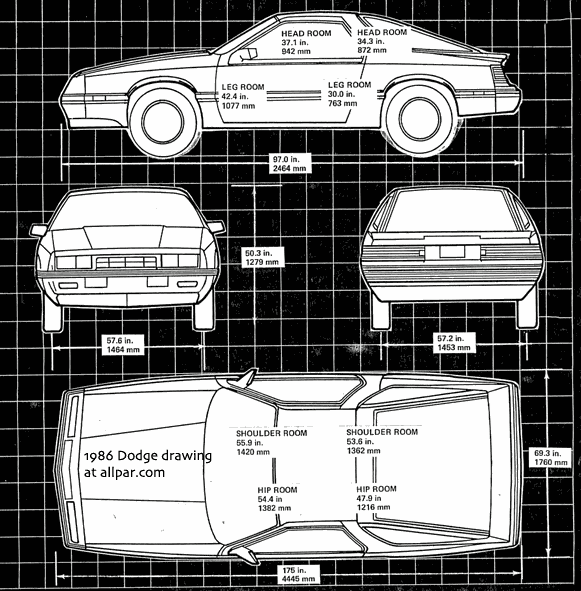

Unlike my Caravan attempt, this time I actually decided to be a bit more accurate. Using !!!error: Indecipherable SUB-paragraph formatting!!! provided by a Google image search (I don't think the car changed too much in a year) and deriving a scale from looking at the picture in Photoshop, we can now look at how much room we have.

After figuring out the scaling of the measurements we can deduce that the dimensions are as such:

Car: 175" L x 69.3" W x 50.3" H

~Engine Area: 57.3"L x 56.5"W x 21.2"H

Now we need a turbine power plant. We could just take an engine off of a passenger jet and duct tape it to the roof, but we need to go under bridges and through drive thrus so a turboshaft would be the most appropriate. Unfortunately, we cannot just yank the engine out of a M1 Abrams and shove it in our engine bay. No, the engine needs to fit (with little adaptation).

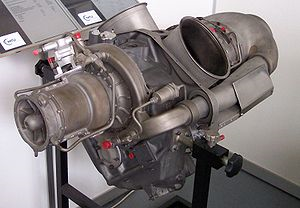

Enter the !!!error: Indecipherable SUB-paragraph formatting!!! , a popular small (-ish) helicopter engine. It's meager 250 shp should be enough to get our machine moving, even with the inevitable power loss between the engine and wheels. It won't be a speed demon, but it will look and sound cool. Given the dimensions of 40.5" L x 22.5" Diameter, only a little bit of adaptation will need to be done to the hood to make it fit. It may need to be mounted upside down so that the exhaust can be pointed away from people's faces.

Speaking of exhaust, it is quite important in this set up because we need to reduce the exhaust temperature as well as the engine noise (however, I don't think people will really care about not being able to hear if they are on fire). Since I am no aerospace or mechanical engineer, I have no idea how long it would take for the gas to cool. The best option would be to hook up a air heat exchanger that will funnel some of the hot exhaust air back into the intake and increase the efficiency of the engine. Pipes would run from the engine exhausts to the heat exchanger where as much of the temperature will be removed from the exhaust air and redirected toward the intake. The exhaust would then be sent out of the back of the car which will hopefully won't set anything on fire.

The drive shaft would come out the back of the turbine to the front or rear wheels (or all wheels hmm...). A RWD setup would be a bit better as there would be less power loss between the shaft and the wheels, but a FWD setup could also be done (as wouldn't require much hacking of the interior). As cool as an AWD jet car would be, I think there would be too much power loss to make it worth it. Ironically a FWD setup would probably be a bit easier. Mount the engine transversely and somehow gear the shaft to the wheels.

That is probably the hardest part of the build. How are we going to get the drive wheels connected to the engine? A traditional transmission wouldn't work, a manual transmission is out of the question (sorry but there are many reasons why it wouldn't work - namely it would break), and a straight connection would be deadly. Honestly I don't know, and after watching the video Chrysler did about their turbine car, I still don't know. Some turboshaft engines operate on a two speed process, some how, I don't know how that works. It probably will need some configuration for city diving and for highway driving. The only thing I can think of is to make a heavy duty clutch that separates the gears from the wheels and have an airplane like throttle control, but an engine that idles at 6000 rpm would probably tear up and attempt at a clutch.

Outside of the major engine components we need to figure out how to wire up all the other major components (power steering, alternator, A/C compressor). Since we probably cannot have a typical serpentine setup, I would think of employing an electric generator and/or motor. Perhaps connect that to the turbo shaft and use the jet to power the generator which in turn would power those other parts. (Of course you could just have the turboshaft go to the electric generator and wire that to electric motors at the wheels and build a jet powered Fisker Karma - oh the thoughts I have mid-writing). Hmm, I wonder if there will be enough room for those components.

Boy this escalated quickly...

Tohru

> bwp240

Tohru

> bwp240

10/27/2014 at 04:53 |

|

This article is a public service announcement for never eating, drinking, or smoking anything Torchinsky gives you. Remember kids, drugs are bad.