by "Duck Duck Grey Duck FTMFW!" (theduckduck)

by "Duck Duck Grey Duck FTMFW!" (theduckduck)

Published 12/11/2017 at 09:53

by "Duck Duck Grey Duck FTMFW!" (theduckduck)

by "Duck Duck Grey Duck FTMFW!" (theduckduck)

Published 12/11/2017 at 09:53

No Tags

STARS: 0

YAY! I FINISHED IT!

It took ALL DAY but I am done. Here’s a linky to day one’s fun

!!! UNKNOWN CONTENT TYPE !!!

Now for a summary of Day 2. I arrived at 8 am looking forward to a day of frustration. Everything went well surprisingly. The only time I was worried was when installing the new timing belt and lining up the marks on the belt with the notches on the cam and crank gears. I spun the engine over by hand like a dozen times making sure everything was lined up. Slapped the covers back on and assorted bits and then moved onto a problem that angered me so.

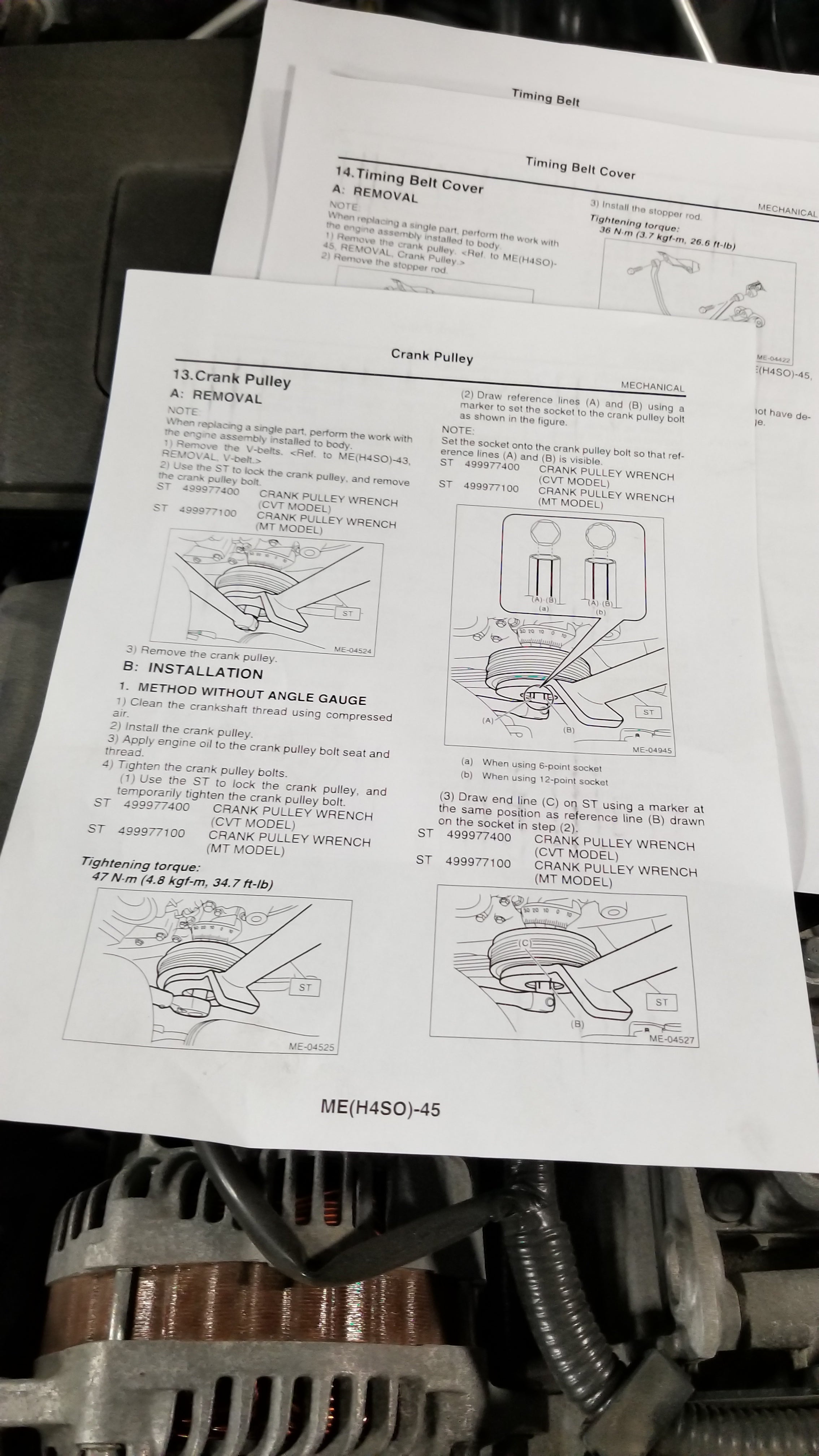

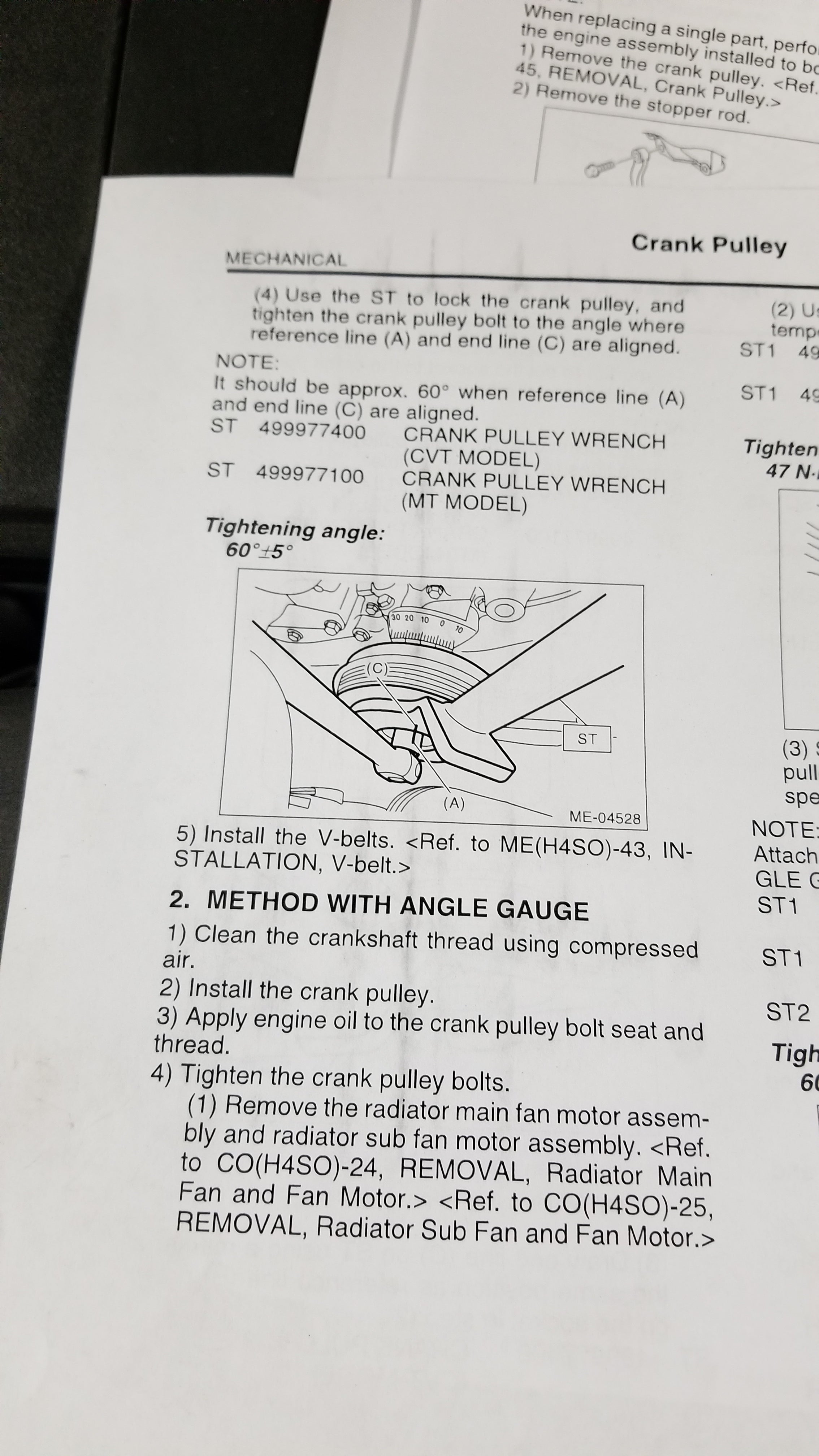

If you don’t have a fancy ass angle gauge thingabob you have to figure out a way to accurately mark the socket your using to tighten the crankshaft pulley bolt! They wanted you to draw lines on your socket. I said eff that. You have to tighten the bolt to 47 newton meters the turn it an additional 60 degrees with +- 5 degree tolerance. They showed a poor way in my opinion to mark the socket so I did this instead:

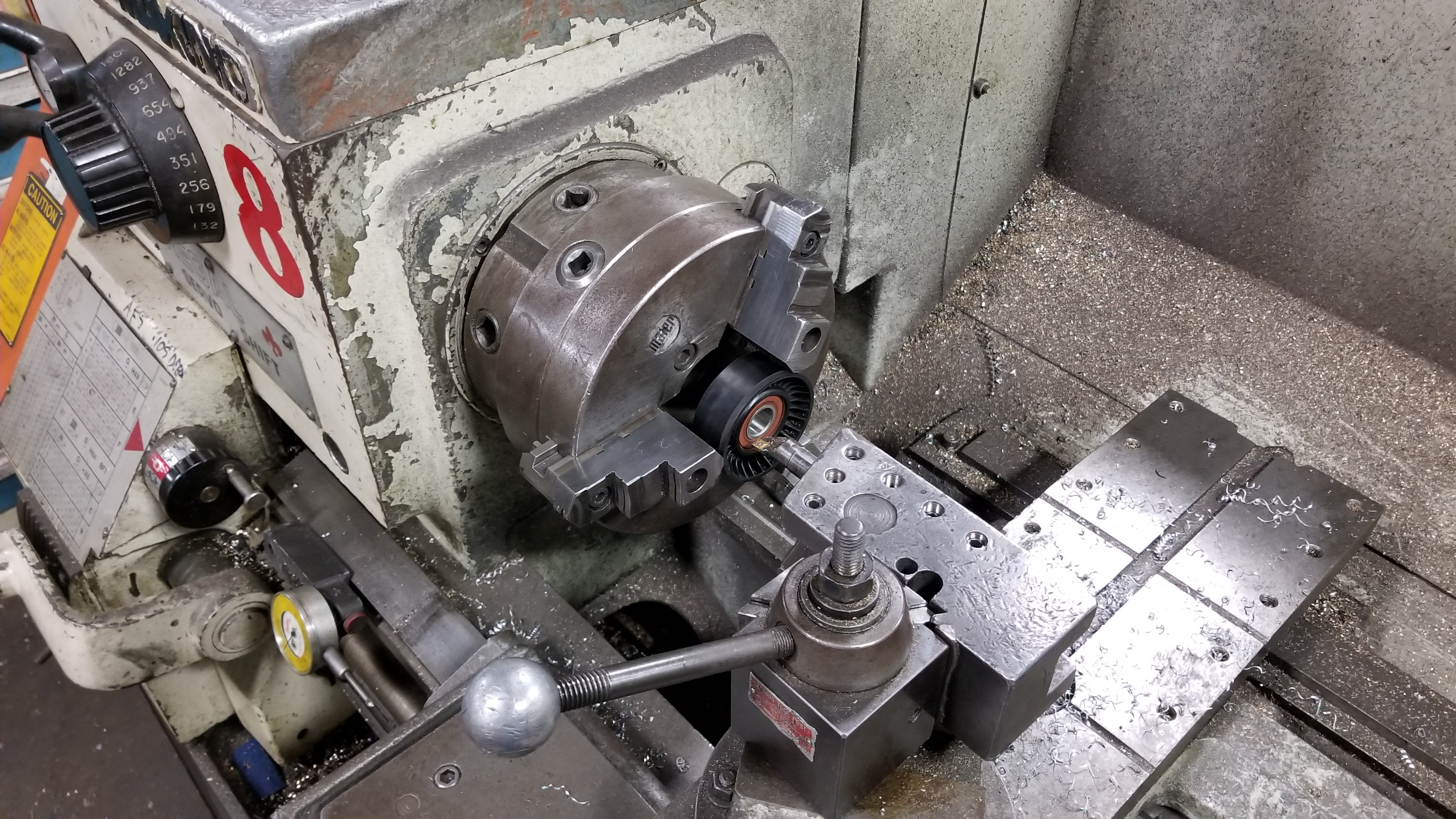

I put the socket in a 6 jaw chuck on the lathe and found the middle of each jaw and used a facing tool to scribe a line into the socket. I considered this way closer than Sharpie marks. After doing this bit of fucking about, I tightened the bolt like they wanted. Okay next problem.

This serpentine belt idler has a bearing that’s locked in there on BOTH SIDES! YOU BASTARDS!

In the lathe it went.

So I pressed the bad bearing out and pressed in a new Koyo bearing because we sell them at work and had it in stock. I slathered the outer race in red Loctite hoping that it helps hold it in there.

FINALLY done with the actually important maintenance issues, I moved on to installing fun things. MUDFLAPS!

I am pretty happy with these. My only complaint is with the hardware. Everything was there but they send you plastic clips for the stainless screws and the very first screw I tried to tighten stripped out the clip. This screw was meant to hold a metal bracket they send for the rear flaps. I replaced it with a stainless 5/16 bolt and NyLock nut. I would have had no faith in the hardware with the original setup. Sorry no pictures of this because it was getting late and I wanted to go home. The rest of the install went fine even though I am now wary that all of the screws for the flaps could fall out at any time : /

I also installed a front license plate holder because I don’t want a bent plate like Mrs. Duck Duck has (and I haven’t fixed yet : /)

Finally I was done, so I put the car back down with my floor jacks. Everyone, I would like to introduce the Hyster Twins:

Thanks everyone for the support on Day 1. I made it. Thanks for reading!

P.S. to the fellow Opponaut who also has a 2012 Outback, I can give you more info and I am also willing to mail you the tool I made to hold the crank and the socket I used.

"pip bip - choose Corrour" (hhgttg69)

"pip bip - choose Corrour" (hhgttg69)

12/12/2017 at 06:07, STARS: 1

timing belts are the devil

Subaru FB motors are better coz chains