by "XJDano" (xjdano)

by "XJDano" (xjdano)

Published 12/08/2017 at 17:00

by "XJDano" (xjdano)

by "XJDano" (xjdano)

Published 12/08/2017 at 17:00

Tags: Equinox

; Head gasket

STARS: 0

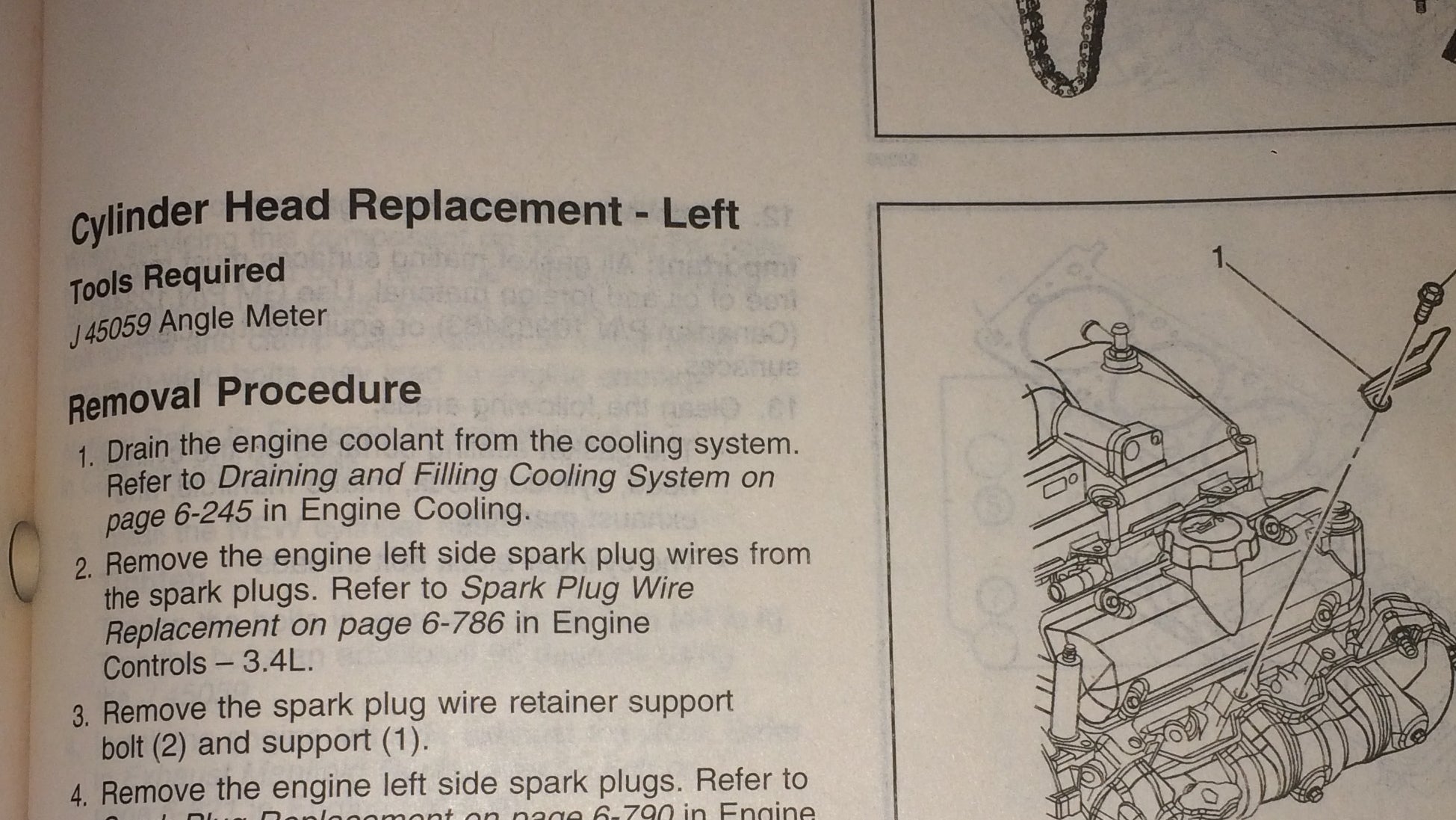

What it is, what it meters And why the FSM says I need it and if I should actually buy this tool that I may only use once.

!!! UNKNOWN CONTENT TYPE !!!

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

12/08/2017 at 17:22, STARS: 3

Sometimes, like when tightening head bolts, part of the torquing procedure calls for turning the bolt a certain angle, like 90° or whatever. I bet this doohickey is the digital version of a torque angle gauge.

"traitor joe" (traitorjoe)

"traitor joe" (traitorjoe)

12/08/2017 at 17:54, STARS: 1

!!! UNKNOWN CONTENT TYPE !!!

based on this demo, I certainly wouldn’t be spending any money on it.

"Jayvincent" (jayvincent)

"Jayvincent" (jayvincent)

12/08/2017 at 18:29, STARS: 0

non-digital version is $5-$10 online...

"jimz" (jimz)

"jimz" (jimz)

12/08/2017 at 18:48, STARS: 3

that’s exactly it. these are “Torque-to-yield” head bolts; you tighten them progressively to a certain # of lb-ft, then in the case of this engine tighten them another 95 degrees. Yes, 95. What happens with TTY bolts is that you are actually tightening them until you reach their yield strength, at which point they are permanently stretched. If GM specifies 95 degrees of tightening after the final torque value, they mean it, and that’s why they say to use a torque/angle meter.

this is also why TTY head bolts should never be re-used.

"Recovering Gaijin" (toxrensem)

"Recovering Gaijin" (toxrensem)

12/08/2017 at 18:51, STARS: 1

Redneck way: speed square and a piece of cardboard. Inscribe your angle on the cardboard. Pierce the cardboard at the point of the angle. Insert socket thru the hole. Take up slack, align breakerbar with base of the angle. >>secure cardboard <

Never broken one yet doing it this way—nor had a head gasket pop. YMMV

ETA: note: I always use a 1/2" drive and a very thick extension to minimize the ‘twist-loss’

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

12/08/2017 at 19:06, STARS: 0

95! Wow, that’s pretty precise. For my car, on the other hand, the manual gives a range: “Tighten all bolts in sequence an additional 1/4 turn (85-95 degrees).”

But if I had to bullseye 95°... yeah, I think I’d want to use a digital meter instead of my analog gauge for that.

"TorqueToYield" (torquetoyield)

"TorqueToYield" (torquetoyield)

12/08/2017 at 19:42, STARS: 1

The 90 vs 95 degrees thing is silly because when you design bolt joints you know that the tolerance range on torque values is something like +/- 30%. Depending on conditions torque values are ridiculously uncertain. So the extra 5 degrees on 95 degrees is for all practical purposes unimportant.

Theres a whole industry based around the measuring of bolt torque (really joint preload force). Most of it costs $$$ though and bolt torque + degree of rotation is close enough.

"AMGtech - now with more recalls!" (amgtech)

"AMGtech - now with more recalls!" (amgtech)

12/09/2017 at 01:52, STARS: 0

So much this. Which is why most people who don’t use torque wrenches religiously don’t destroy everything they work on. Torque varies so much because of so many different factors it’s ridiculous. What condition are the threads in? How tightly do they fit? Are they dry? Is there a fluid under the head of the fastener? What type of fluid is on the fastener or threads? Etc etc etc. Basically, torque specs are in the range of tight enough not to loosen and loose enough not to break.