by "Spanfeller is a twat" (theaspiringengineer)

by "Spanfeller is a twat" (theaspiringengineer)

Published 11/30/2017 at 10:41

by "Spanfeller is a twat" (theaspiringengineer)

by "Spanfeller is a twat" (theaspiringengineer)

Published 11/30/2017 at 10:41

No Tags

STARS: 0

My hanger has not arrived, I craved in and went to a local shop so that they would machine one, yesterday I came in to see their 800 peso (43USD!!) aluminum, handmade hanger, just to realize it was a piece of shit.

It was crooked and it didnít alling with the screw holes, this because instead of using the picture I sent them of the factory catalogue, they instead used my crooked,bent hanger as a fucking basis for their new crappy ass hanger.

I complained about this, just for the store owner to piss on me saying that ďThey do much more expensive bike hangers and they donít complainĒ and ďYou shouldíve given us a correct base for us to make the hanger.Ē But the thing is: I did give them the picture of the factory hanger, in fact, I gave it to the store owner, the clerk, and the machinist. when I asked for my bent hanger they went hands up and basically asked me to give them money for what is basically trash.

Later on the mechanic sent me a pissing message saying that it was, again, my fault. But that he would gladly ďbend it into shapeĒ if I brought my frame in.

Now, Iím no materials expert, but I do believe that thereís this thing called ďmetal fatigueĒ and that you canít simply bend aluminum into place, not without messing with the frame you canít!

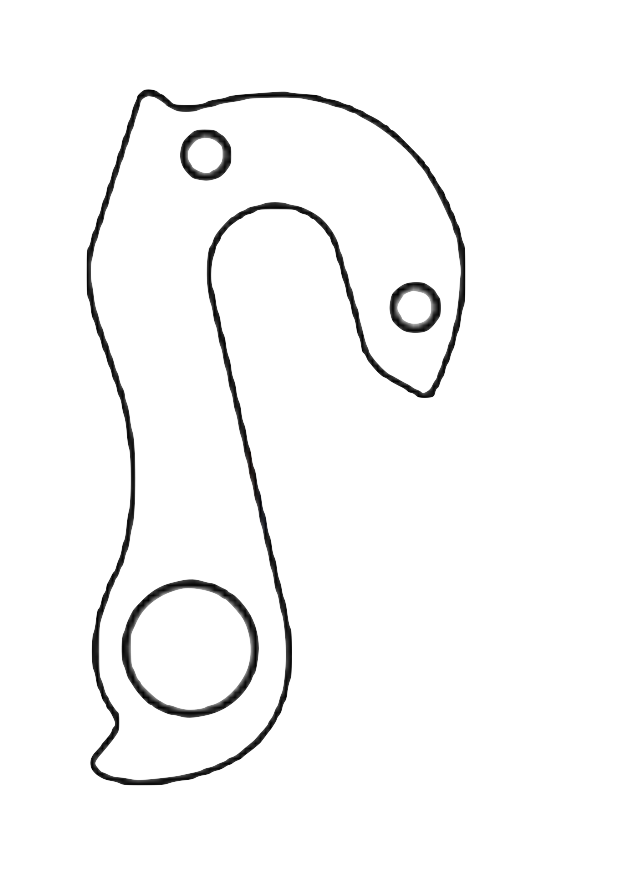

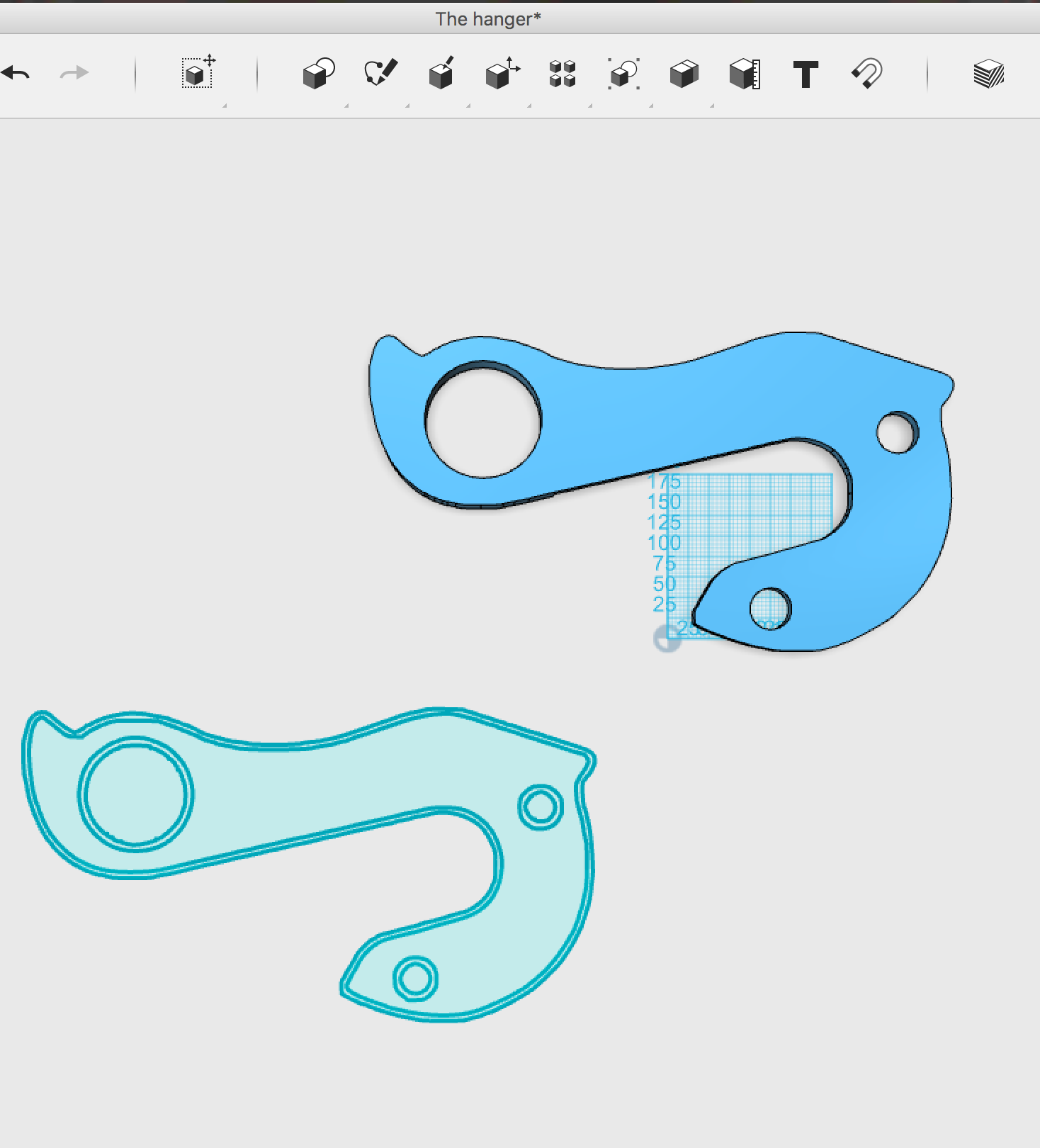

He said the picture wasnít to scale and that he couldnít work that way, it was too much work. So instead I vectorized the picture, made it using CAD software and now will use the universityís cutting machine to make my own part with help from my friends in materials engineering.

Itís still very much work in progress, I need to measure dem holes more accurately and scale it. For that I shall be measuring my bikeís frame because the stupid shop kept my bent hanger. I donít know if its too much work for a professional machinist, after all, Iím just a dumb teenager and it took me the most excruciating 15-minutes of my lunch time.

Anyway, I found it just dandy that they would complain about doing their job correctly. I feel sorry for the owners of the ďmore expensive bikesĒ that had the harrowing experience to work with these people.

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

11/30/2017 at 10:51, STARS: 1

While they suck, this is kinda on you. They need actual dimensions to make something. A picture with a scale in a 1-1 format might have sufficed but an actual drawing of what you wanted is what you should have handed to them.

Aluminum wonít fatigue out with the amount of cycles that a bike hanger sees. You need tens of thousands of cycles to fatigue it out when you donít go past yield.

Going past yield is a different story.

"Mini Guy- Now has a 4Runner" (gavinharter30)

"Mini Guy- Now has a 4Runner" (gavinharter30)

11/30/2017 at 10:52, STARS: 0

So extra :)

"benjrblant" (benjblant)

"benjrblant" (benjblant)

11/30/2017 at 10:56, STARS: 0

Iíve straightened many a hanger before. Do it properly and it will suffice- at least until you can secure a suitable replacement. I usually advise carrying an extra hanger in a larger toolkit or keeping one at home- along with a chain, a set of pads, some spokes, and a shift cable.

"Ash78, voting early and often" (ash78)

"Ash78, voting early and often" (ash78)

11/30/2017 at 11:03, STARS: 4

Aspiring Engineer be like:

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

11/30/2017 at 11:18, STARS: 0

I guess it could, but Iím not paying forty dollars for a straightened hanger! They told me that they had this awesome machinist who could make hangers professionally, thatís why I was prepared to pay 40 dollars, but I canít buy a bent hanger for so much money!

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

11/30/2017 at 11:20, STARS: 0

You are still stressing the material without need, plus, I am not paying 40 dollars for an aluminum hanger that was made without regard and then twisted into shape.

I suppose I couldíve made the drawing, but I expected them to be much more professional, they couldíve printed the picture with one on one format but they didnít and they knew they had to print the picture because I told them about it.

While I understand what they did, it was an excuse.

"benjrblant" (benjblant)

"benjrblant" (benjblant)

11/30/2017 at 11:22, STARS: 0

All thatís required to straighten a hanger well enough to ride a handful of KMís out is a hammer and a flat surface or two rocks if youíre in a pinch. If the hanger is snapped, a chain tool can easily convert your bike to a single speed in an emergency.

If you find yourself frequently bending hangers, a Park tool DAG-2 might be up your alley, but at $75US, its really more of a pro shop tool.

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

11/30/2017 at 11:25, STARS: 0

I mean, its the first hanger iíve ever bent. I will probably stock up on my own tools though, the bycicle shops here are outrageously expensive

"benjrblant" (benjblant)

"benjrblant" (benjblant)

11/30/2017 at 11:27, STARS: 1

I worked in a shop in college, so I had a fair bit of knowledge. I found that often it was less expensive to purchase a tool than to pay a shop. Iíve been slowly building my toolkit. I had a post about it a few weeks ago here . Offering to do a few quick fixes on friendsí bikes for a few dollars on the side has also offset the cost of the tools.

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

11/30/2017 at 11:28, STARS: 0

...I expected them to be much more professional...

Thereís your problem.

I recently analyzed a gear for a client. This particular gear was originally designed with one piece cast construction. They were given the original drawings and told to make a new one. The machine shop produced a gear that didnít look anything like the old one with some weird marks on it.

What the machine shop did is construct it in two pieces to save costs. They then laid down a weld and milled it back to make it appear as though it was one piece. We caught what they did and after much back and forth they owned up to it when we told them we wouldnít sue for the money back. Not worth it for a gear that only cost a couple thousand dollars.

This gear wasnít all that important, just the main drive gear for a ~100,000 lb gate.

Shops will constantly try and pull shit.

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

11/30/2017 at 11:39, STARS: 0

Sons of bitches!

Yeah, perhaps I should treat them with less regard. What hurts me is that they are the neighborhood bike shop and like, theyíre my fucking neighboors, I canít believe they treated me this way.

I know that my frame isnít a fancy ass frame as they said, and that perhaps I didnít print the picture. But I trusted them and they turned around and insulted me and treated me like an idiot.

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

11/30/2017 at 11:40, STARS: 0

That is great! Iíll stock on my own tools too!

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

11/30/2017 at 12:31, STARS: 0

Thatís life. You learn and move on.

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

11/30/2017 at 12:36, STARS: 0

Yeah, youíre right.

I guess I am just a dumb teenager.

"Spoon II" (Spoon_II)

"Spoon II" (Spoon_II)

11/30/2017 at 13:48, STARS: 0

That sucks, but yeah, itís definitely a learning experience, and points to a really valuable lesson:

When dealing with machinists, shops and manufacturers, always provide a ridiculous amount of detail (more than you think you need), because itís kind of shocking how often people will mess up making something. Then at least you have the evidence, and it wins arguments for you.

"Chariotoflove" (chariotoflove)

"Chariotoflove" (chariotoflove)

12/01/2017 at 15:46, STARS: 0

I hope you didnít pay for the bad piece.

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

12/01/2017 at 15:51, STARS: 2

Nope, didnít get a single peso outta me!