by "450X_FTW" (mistermic)

by "450X_FTW" (mistermic)

Published 11/08/2017 at 10:00

by "450X_FTW" (mistermic)

by "450X_FTW" (mistermic)

Published 11/08/2017 at 10:00

No Tags

STARS: 1

Doing an axle swap on our Jeep, since the stock gearing is 3.07 and I found a set of axles with 4.11 gearing that are a bolt on (front is Dana 30, rear is Dana 35, same as our current). Before attaching though, they need some work. The diff is perfect for having 129k miles, almost no lash at all, and seals are great. Brakes I planned to redo entirely, wire wheel all the rust off, and apply a nice coat of POR15 to the axles when done.

I wanted to replace every spring, cable, connection in the drums, since they were over 20 years old, and I don’t want to have any problems.

So, step 1, repeat until free. Turns out it would not be free, because the retaining springs were broken, meaning the shoes were pushed against the drum and Clarkston style hammering would not break them free.

After much aggravation, this is the amount of corrosion build up you can expect inside a drum brake of a 20+ year old jeep on Michigan roads

Since everything was old and brittle, it came apart pretty easily. Took a wire wheel to the insides cleaning them up, hit it with a can of primer and sealer

So, new shoes, drums, springs, retainers, parking brake cables, master cylinder,etc later, all for about $200. But holy crap it took A LOT of fighting to get everything to line up. How the hell does someone invent something so complicated compared to disc brakes? Yes yes I know drum brakes have advantages, but still, holy complex design.

"jimz" (jimz)

"jimz" (jimz)

11/08/2017 at 10:06, STARS: 3

I took shop class in the early ‘90s and was a wrench for a number of years after, and I could do conventional drum brake job blindfolded (assuming it wasn’t all locked up like yours.) I had all of the proper spring tools, however.

but that didn’t prepare me for my Ranger. it has rear discs, but the parking brake is a “drum in hat” type where inside the rotor is a small cable-actuated drum brake. Holy balls was that thing a pain in the ass to put new shoes in.

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 10:10, STARS: 0

Our jeep is a 94 and the parking brake has never been used (according to the previous owner) so I didn’t want to take any risks with it locking up if I tried to use it.

"Tripper" (tripe46)

"Tripper" (tripe46)

11/08/2017 at 10:12, STARS: 0

Ugh, my Ranger has rear drums. luckily they were replaced just before I bought the truck. I’ve talked to someone who swapped the rears out for discs from a mustang of the same generation, but I did not consider the parking brake. I wonder how that plays in to a swap like that.

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

11/08/2017 at 10:16, STARS: 0

I don’t understand the need for a separate parking brake assembly. My Mustang’s rear calipers have a provision for parking brake cable operation, so both the service brake and the parking brake use the same calipers and pads.

Could it be a weight thing? Do pads just not have enough surface area to hold a heavier vehicle?

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

11/08/2017 at 10:41, STARS: 0

The horrors of incremental design. A basic drum brake is a pin, a casting with three easily finished surfaces, another casting with a lathed surface, a piece of sheet metal, two other pieces of sheet metal, and one or two springs. A basic disc brake is conceptually simple, but the pieces involved require better manufacturing processes and better materials to make sense.

Therefore, a process of “constant improvement” adding greater and greater complexity to the “simple” drum to overcome its deficiencies is often “easier” than to get the QC and design of the disc perfect. The devil is in the details. It’s kind of the steampunk/valves and steam and cylinders sort of paradigm vs. electricity - if you don’t have a better way to solve the problem handy, you embroider what you have that works. Reference a mechanical player piano... It’s not even that the discs were impossible, just touchy and fiddly up until relatively late, and even now, often carry some extra costs.

Take for example the hydraulic component. The cylinder has a bore, easy to turn out, two hydraulic taps (line and bleed), and points of fixture. The caliper has a much larger bore, which is trickier, more involved casting to produce, more difficulty in the hydraulic taps, and either a bunch of extra hardware to slide, or more cross-piping, internal sealing, and shenanigans with an extra bore. All of which in either case has to be *perfect* to prevent a dragging caliper on one side. Not necessarily hard, but the pennies add up.

But it doesn’t just stop with the steel. The seal in the caliper is much larger, *and with tight tolerances*, because the seal cannot afford to restrict the piston from retracting. (The piston is also much more expensive.) The seals in the cylinder can be all over the fucking place, and as long as the springs are strong enough to retract them and they don’t leak, nobody gives a shit. The seals in the cylinder (as opposed to the caliper) also don’t have to be as good material, because they’re not getting baked in the same way except in hard brake cycles.

Then the friction surfaces. The disc pad surfaces have to be a compound with a lot of bite, hard-wearing, yet glassy smooth when in light contact. The drum compound can be awful powdery garbage, but has so much surface area that it will get into shape *once* and not offer necessarily as much trouble going forward.

As to the design of the thing, the disc pad and caliper have to be sized somewhat appropriately so that they apply enough force but still retract adequately, which is harder than it sounds. Drums... who cares? Springs, yo. The disc has to be designed to shed heat properly, whereas if your application involves simple drums, you probably don’t care about fade too much, so let’s just dump light heat releases into this lumpy fuck-off casting here....

A casting which has typically been just plain cheaper to make than a rotor.

At the end of the day, the “embroidered” drum setup doesn’t have that much of an advantage cost-wise over the discs, but for a lot of auto history it really did, which drove slow adoption and enabled a lot of bad design habits in the “embroidery”. Hell, the sneaky costs of disc setup enabled a lot of bad habits for disc arrangements too - see captive rotors, hub rotors, and so on.

It’s easy to look at a simple option vs. complex option dichotomy and “WTF” straight into assuming the simple option is obvious, but sometimes it’s the truth that’s complicated.

The RamblinRover Treatise on Drum Brakes: The Why of “WHY? WTF?”, and How Design Engineering Can Suck

"jimz" (jimz)

"jimz" (jimz)

11/08/2017 at 11:00, STARS: 1

You know what the really stupid thing is? The Mustang and Ranger use the same axles! my Ranger has the 8.8" axle, and my 2010/2012 Mustangs had the... 8.8" axle. Yet the Ranger is drum-in-hat, and the Mustangs mechanically actuated the calipers.

I’ve no idea why.

and I can tell you with certainty those stupid little drums inside the rotor are borderline worthless.

"Steve in Manhattan" (blogenfreude01)

"Steve in Manhattan" (blogenfreude01)

11/08/2017 at 11:01, STARS: 0

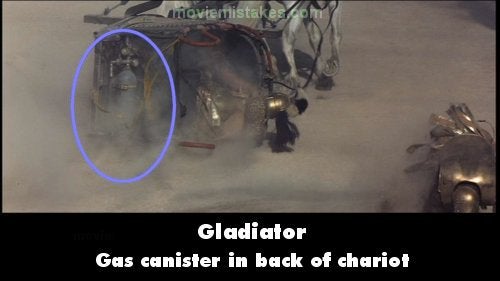

Julius Caesar’s chariot had drum brakes ...

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 11:17, STARS: 1

He also put air compressors in the back of chariots. Makes them flip over easier. Not the smartest guy

"Stapleface" (patrickgruden)

"Stapleface" (patrickgruden)

11/08/2017 at 11:30, STARS: 1

Yeah, drums are a major PITA. Which is why I’ve never even bothered on my wife’s Corolla. She’s got 104k now and I’ve done the front pads twice. As long as it still stops well I’m not touching the drums.

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 11:32, STARS: 1

With these having 120k on them from the guy I bought them off of (parting out his jeep), I assumed they had never been done, and I was right. The pad on the shoes was more brittle than glass. I was able to break it off with just my fingers.

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

11/08/2017 at 11:48, STARS: 0

Drum brakes are like carbs to me. I have no need for them.

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

11/08/2017 at 12:16, STARS: 0

I just checked my Mustang’s (1995) GVWR: it’s 4,521 lbs, and I assume the stock parking brake is supposed to be enough to hold that much weight on a hill. Google tells me that a Ranger’s GVWR could be up to 900 lbs more than that, but aren’t the Ranger’s pads much bigger than the Mustang’s?

Seems to me like it would have been sufficient to use the same setup on a Ranger, given those larger pads. I doubt that the whole drum-in-hat setup was cheaper for Ford than simply using dual-activation (not sure of proper term) calipers.

"crowmolly" (crowmolly)

"crowmolly" (crowmolly)

11/08/2017 at 12:24, STARS: 2

Easy with the POR15. A wire wheeled axle can be too smooth for proper adhesion. If it’s clean, smooth mental just go with epoxy and a topcoat. Trust me, that shit will peel if the metal isn’t rough enough. I’ve got two repairs to do on POR’d surfaces this weekend due to improper tooth.

"gogmorgo - rowing gears in a Grand Cherokee" (gogmorgo)

"gogmorgo - rowing gears in a Grand Cherokee" (gogmorgo)

11/08/2017 at 12:27, STARS: 1

I picked up some factory 4.10 geared axles for my Jeep recently too. A little beefier than yours though. I had a 4.10 disc brake c8.25 from a KJ to go into it, but these will bolt straight in:

At least I hope. The AMC20's pinion looks like it sticks out ~3/4" further than the d35's, and that’s about how much room I think I have left on the driveshaft yoke so it may be a little close.

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 12:42, STARS: 0

Good to know! The surface is still pretty rough, the wire wheel was just in my coredless drill to get the years of corrosion build up off the axle housings. If I use the electric grinder with a wire wheel, yeah that’ll put a shine on it.

"greasemonkey235097" (greasemonkey235097)

"greasemonkey235097" (greasemonkey235097)

11/08/2017 at 12:42, STARS: 1

8.8 swap time!

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 12:44, STARS: 0

From doing research, I found out the YJ with 2.5L had 4.10 gears stock, since they had crap for torque, extra low gearing would make it feel like it was quick.

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 12:46, STARS: 1

That was on the possibilities list, but I don’t trust my fab skills just yet for bracket relocation. If I grenade this one, then I’ll step it up to the 8.8.

"gogmorgo - rowing gears in a Grand Cherokee" (gogmorgo)

"gogmorgo - rowing gears in a Grand Cherokee" (gogmorgo)

11/08/2017 at 14:09, STARS: 1

Yup. Same deal for me really. But also towing package.

"Steve in Manhattan" (blogenfreude01)

"Steve in Manhattan" (blogenfreude01)

11/08/2017 at 20:42, STARS: 0

How do you think Charlton Heston won that race?

"450X_FTW" (mistermic)

"450X_FTW" (mistermic)

11/08/2017 at 22:14, STARS: 0

Was Charlton Heston the little wizard one with the rings?