by "RamblinRover Luxury-Yacht" (ramblininexile)

by "RamblinRover Luxury-Yacht" (ramblininexile)

Published 11/03/2017 at 14:15

by "RamblinRover Luxury-Yacht" (ramblininexile)

by "RamblinRover Luxury-Yacht" (ramblininexile)

Published 11/03/2017 at 14:15

No Tags

STARS: 5

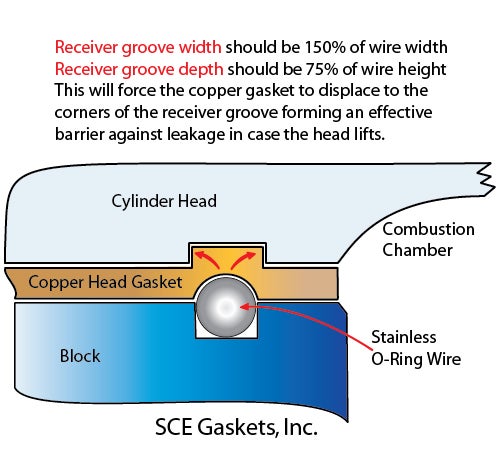

So, apparently on some race engines and otherwise weird engines from the 60s-70s, ordinary head gaskets of the day were just too inferior. So, they use not only a copper head gasket, but an extra metal ring to focus pressure on the copper...

Why did I learn this? Because my dad had to do a head gasket on a Midget with the 1500 Spitfire engine, and some of them have these. Stock, in a *shelf* that looks like a liner edge, rather than a groove. Some bozo in the past removed them, slapped it together with sealant, and when my dad got the head back on (not having known what he was looking at), it leaked like a mofo.

This forum post

provided further details on specs, once I knew what I was looking for. Apparently a lot of these blocks get milled flat, because deleting .030 for raised compression and getting rid of asinine wire lunacy sounds pretty awesome.

"RutRut" (RDR)

"RutRut" (RDR)

11/03/2017 at 14:20, STARS: 1

This is pretty normal still in the performance diesel community, just look up “fire ring heads.” Basically they just have too much compression and boost to live for long with normal head gasket setups, the really powerful guys are going well over 100 psi of boost.

"Sweet Trav" (thespunbearing)

"Sweet Trav" (thespunbearing)

11/03/2017 at 14:23, STARS: 3

yeah O-ringed heads and blocks are actually the best possible way of sealing the chamber.

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

11/03/2017 at 14:30, STARS: 2

Subaru lunatics do this too, when you want over 800hp from a 2.5L 4 cylinder its a great way to keep the head sealed to the block

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

11/03/2017 at 14:36, STARS: 1

“Because I’m doing something stupid” is usually the best explanation for using a solution that’s a figurative primitive sledgehammer like this. But if it works...

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

11/03/2017 at 14:41, STARS: 5

To use a primitive and really effective solution in a really half-assed way and randomly to fix a problem that shouldn’t have existed, as cheaply as possible but with a lot of labor involved... well, that’s more or less the most quintessentially British thing I’ve ever heard of.

"Sweet Trav" (thespunbearing)

"Sweet Trav" (thespunbearing)

11/03/2017 at 14:44, STARS: 0

Assuming the heads dont lift lol.

"CalzoneGolem" (calzonegolem)

"CalzoneGolem" (calzonegolem)

11/03/2017 at 14:49, STARS: 2

Because I’m doing something stupid

That’s a funny way to spell awesome.

"ateamfan42" (ateamfan42)

"ateamfan42" (ateamfan42)

11/03/2017 at 15:17, STARS: 0

There also exists the approach of having the groove in the head or block, but NOT using the o-ring. The idea being that the gasket is compressed everywhere but where the groove is, providing a similar mechanical interlock.

Such practices (with and without the o-ring) have been played with in the forced induction world for a while. When you drive the cylinder pressures up, you gotta keep that pressured sealed somehow.

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

11/03/2017 at 15:20, STARS: 0

The biggest problem with this, on said Midget, is that my dad tried to use a modern multi-layer head gasket, and the little seal ring which does this sort of job normally was... wait for it... floating in space in the o-ring shelf. Which is not a groove. It would have probably been fine if it was a groove and not a shelf, because either no engagement at all, or the kind you describe.

"You can tell a Finn but you can't tell him much" (youcantellafinn)

"You can tell a Finn but you can't tell him much" (youcantellafinn)

11/03/2017 at 15:22, STARS: 2

"benjrblant" (benjblant)

"benjrblant" (benjblant)

11/03/2017 at 15:37, STARS: 0

No Far Side comics today? )=

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

11/03/2017 at 15:41, STARS: 1

Work and a home improvement project and research for a couple of things kept it straight out of my head. First one posted now.

"benjrblant" (benjblant)

"benjrblant" (benjblant)

11/03/2017 at 15:45, STARS: 0

All understandable reasons! No worries!

"For Sweden" (rallybeetle)

"For Sweden" (rallybeetle)

11/03/2017 at 17:02, STARS: 1

The British were big on being near-socialism at the time, so lots of labor makes sense.

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

11/06/2017 at 10:50, STARS: 0

If you’re doing this you’re also using some gnarly head studs like arp 625+ or some custom oversized half inch ones and torquing the bejesus out of them too.

Then you’re just fighting the whole block deforming from all that pressure, so you’ve also got a closed deck insert bashed in and decked off too.

"Sweet Trav" (thespunbearing)

"Sweet Trav" (thespunbearing)

11/06/2017 at 11:47, STARS: 0

Nah, depends on the head. the SBC’s that I see o ringed just use standard ARP studs, 5 five per cylinder, with their locations is enough to keep things square. as for the block deforming, not an issue with a proper closed deck block like a SBC, BBC or LS motor.

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

11/06/2017 at 14:34, STARS: 0

Yeah, I’m talking silly subaru land. What’s the fun in using a “proper” engine like those haha

You’d need to be making like 2000hp to justify this process with that much displacement

"Sweet Trav" (thespunbearing)

"Sweet Trav" (thespunbearing)

11/06/2017 at 15:58, STARS: 0

Depends really. Its all about durability. Sure you can slap a big turbo on a 5.3l with LS9 head gaskets and SEND IT , but you’re only going to get a season or two out of it. An O-ringed motor can take A LOT of abuse and stupid high cylinder pressure, assuming the pistons and bottom end can handle it it will last for years and years...

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

11/06/2017 at 16:21, STARS: 0

No question, but still O-ringing a motor is well outside the purview of the average weekend warrior.

reserved for proper lunatics haha

"Sweet Trav" (thespunbearing)

"Sweet Trav" (thespunbearing)

11/07/2017 at 09:33, STARS: 0

I mean 500 HP at the wheels used to be reserved for super cars and people with 15K to blow on an engine. Now you’re a junkyard 5.3l and a $400 EBAY turbo away from 500-600 hp at the tires.

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

11/07/2017 at 09:41, STARS: 0

It’s an amusing world we live in right?

My point was that there are a great many things to be addressed in a set up like that long before o-ringing the engine makes any sense. No point even thinking about it until you’re pushing 3-4 bar of boost through it, with that size engine you’re looking at that 2000hp we discussed earlier and that special class of lunatics trying to run sixes

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

11/10/2017 at 11:53, STARS: 0

Huh, here was me thinking that this is pretty common practice for some engines. They call them ‘recessed block’ engines and they’ve basically got a stainless ring that runs in a groove around the outside of the cylinder wall along the face of the block. Got the same thing on my Spit’s engine.

Can’t imagine someone gumming it up with sealant though. What a silly idea...

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

11/10/2017 at 12:38, STARS: 0

It’s apparently a thing for very few engines outside a Spit 1500. The mystery actually deepens, because it seems that the Payen composite gasket for a 1500 has the ring made in, in such a way that it’s meant not to require a “proper” copper gasket and free ring. Except, it seems that the gasket my dad went back together with was the *correct* Payen gasket and it didn’t work properly for some reason. Quite odd. At any rate, he’s been having an ongoing problem with stuck rings, so he finally decided to tear it down. In the process, he’ll be going back with ARP studs and be checking the block and head for true if not lightly skimming, so this may clear up...

Now, if Rover had used a gasket of this type on the V8, milling their liners to a recess, and had shaped the combustion chamber properly to avoid the lip... that and a cut to ten head fasteners from fourteen and proper studs (not bolts)...

Well, let’s just say there’d be a little less infamy..