by "sn4cktimes" (snacktimes)

by "sn4cktimes" (snacktimes)

Published 10/14/2017 at 11:45

by "sn4cktimes" (snacktimes)

by "sn4cktimes" (snacktimes)

Published 10/14/2017 at 11:45

No Tags

STARS: 0

Iím getting ready to modify a set of Jeep headers to fit my AMC Eagle. Iím already a welder so one hurdle down. Have a TIG welder showing up Monday, so thatís another problem solved. Have 309 rods and Argon gas. But I donít really know anything about exhaust systems.

Iíll be cutting off the bottom of the header and changing the angle of the last pipe section to point away from the engine by about 45 degrees to clear an engine bracket that Jeeps donít have. I need to know about FLANGES and how systems connect together. It currently has a 2 bolt flat flange that leaves a little of the 2.25" OD pipe sticking through. My exhaust pipe is 2" OD and had the end cut right off due to clearance and being seized with 29 years of rust. The header came with a little sintered donut thing which is not how the factory setup worked. The factory system seemed to just crush the exhaust pipe up into the flared base of the original cast manifold.

What are my options here? Keeping in mind Iíll have 2 virgin ends to work with.

Should I weld on 2 or 3 hole flanges? Iíve read 3 hole seal better. Do I need a gasket? How does this donut thing work? Should I use a ball a socket flange? Does there need to be flex at that point? Should I use a reducer?†I know nothing! Tell me all the things!

"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

10/14/2017 at 13:27, STARS: 2

There are many options for you here, (hence your dilemma) but given your position as a fabricator I would suggest using budget parts to go with the trick, modern solution to this problem.

A flex pipe connected to a V-band flange is a super-durable, super-serviceable configuration. This was once expensive racecar-only stuff, but you can now get cheap parts from Summit racing.

They do a house-brand V-band clamp that is very good so long as you replace the idiotically-chosen nylock nut with a simple pair of plain stainless jam-nuts:

Then you simply throw a 2.25 inch (or whatever diameter you need) flex pipe on whichever side of the v-band clamp packages better:

And Bobís your aunty. This configuration is used frequently in big power turbo builds, so concerns about its durability under heat stress or vibration loading are pretty unfounded. Itís basically a perfect solution aside from the fact that it uses fairly expensive components and needs a good amount of planning and fabrication skill to make it work correctly.

Flanges with gaskets and donut-seals are popular because they work so reliably on a high-speed assembly line. Given that you are essentially building your own one-off custom exhaust, thereís no need for such time-saving mass-production measures.

A flex pipe and V-band will allow you to cleanly connect your headers to the rest of your exhaust system while also isolating it from engine vibration. As far as your problem with tube size thatís pretty much up to you. You could weld in a reducer, probably on the downstream side of the V-band clamp, or you could just run 2.25 inch tubing all the way to the back of the car (if Iím not mistaken in thinking you are completely replacing the original exhaust system).

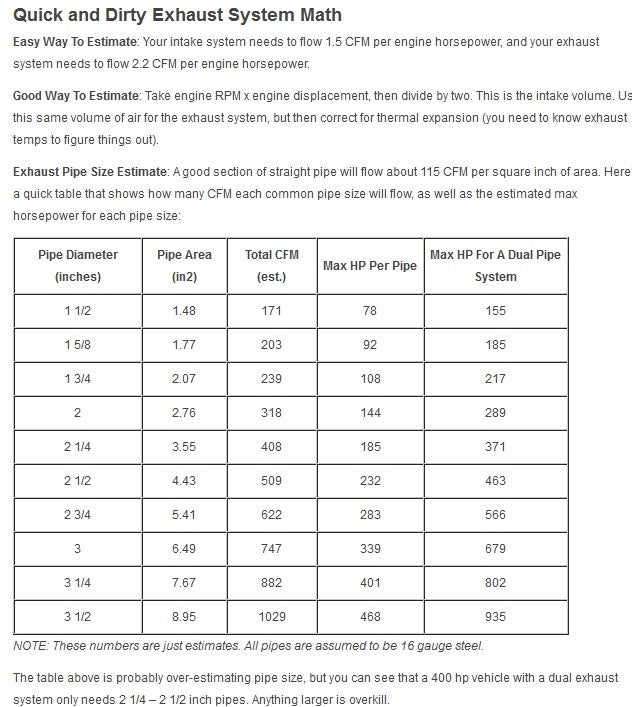

That decision is yours, though I can provide you with a rough guide to the mathematical side of the choice:

!!! UNKNOWN CONTENT TYPE !!!

"sn4cktimes" (snacktimes)

"sn4cktimes" (snacktimes)

10/14/2017 at 17:11, STARS: 0

That was VERY helpful! I read a bunch more stuff and this and ended up with pretty much exactly what your suggestions are. Iím going to chop off the bottom of the header, add one or two bends (not sure yet), install a V-band flange, then install a flex pipe with VBFís on both ends and then for now just weld a flipped 2.5-2" mild steel reducer with a VBF onto the still stock system. The removable flex section will add a bit of cost but make underside engine access easier without having to remove the intake manifold and the header. Then when Iím ready to change the rest of the pipes and the muffler itíll be no hassle to go with 2.5" pipe all the way back.

"MM54" (mm54mk2)

"MM54" (mm54mk2)

10/15/2017 at 13:35, STARS: 0

Ball flanges are nice, but if youíre going to be custom making the whole system Iíd say go with a v-band

"sn4cktimes" (snacktimes)

"sn4cktimes" (snacktimes)

10/16/2017 at 00:45, STARS: 0

Yeah, I went with V-Band.