by "ImmoralMinority" (araimondo)

by "ImmoralMinority" (araimondo)

Published 10/07/2017 at 10:17

by "ImmoralMinority" (araimondo)

by "ImmoralMinority" (araimondo)

Published 10/07/2017 at 10:17

No Tags

STARS: 4

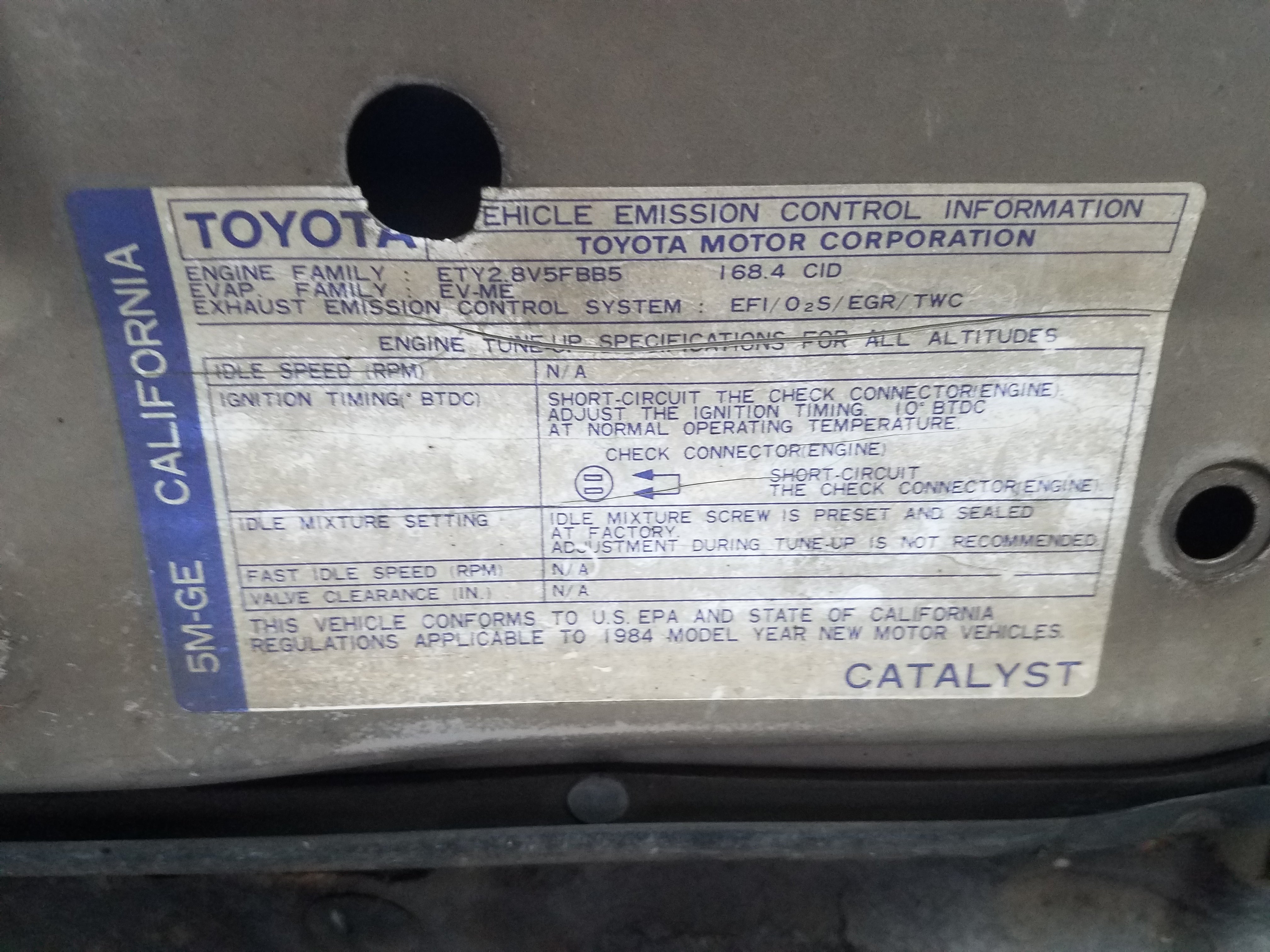

I need to wash the Sunchaser, but today my focus is on the Cressida.

I am changing the valve covers, because one is warped and leaking. I have beautiful restored OEM covers and new gaskets.

I have never done this before, and am watching videos over my morning coffee. Any Oppo pointers? One of you must have done this on a Supra with this engine.

"pip bip - choose Corrour" (hhgttg69)

"pip bip - choose Corrour" (hhgttg69)

10/07/2017 at 10:20, STARS: 4

take a lot of pics before disassembly and label where the hoses go too.

"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

10/07/2017 at 10:25, STARS: 3

If you have the option to, blow compressed air all over the area so you donít have to worry about any grit dropping into the valvetrain when you pull the covers off.

"crowmolly" (crowmolly)

"crowmolly" (crowmolly)

10/07/2017 at 11:17, STARS: 1

What are the gaskets made of?

Depending on the material Iíll use some high-tack on the valve cover side to keep the gasket in place.

PS looks like you need to change your brake fluid.

"shop-teacher" (shop-teacher)

"shop-teacher" (shop-teacher)

10/07/2017 at 11:19, STARS: 0

Be gentle, and tighten those covers down evenly, little by little.

"Junkrat aka Rick Sanchez: Fury Road Edition" (realasabass)

"Junkrat aka Rick Sanchez: Fury Road Edition" (realasabass)

10/07/2017 at 12:02, STARS: 0

If it is a car I have to adjust valves on regularly, I will dot the head side with a few dots of chapstick. That way it always comes off in ine piece. Iíve never had a problem with leaking.

"notsomethingstructural" (notsomethingstructural)

"notsomethingstructural" (notsomethingstructural)

10/07/2017 at 12:07, STARS: 2

Few things - I havenít done this engine but Iíve done my share of valve cover gaskets.

1. Get the torque specs and sequencing for the bolts. Theyíre usually on the order of 8-12 ft-lb BUT some are shouldered positive stop bolts and if youíll shatter the bolt if you donít, well, stop. No torque specs for those, itís barely more than finger tight. Sequencing is important too, some want corners first some want corners last.

2. Check that there are no points for RTV. Many manufacturers for their†VCG jobs want you to put a bead in the corners or anywhere it isnít flat.

3. Clean the hell out of both mating surfaces. Scrape the head with a razor blade then either wire brush or *lightly* sand with 220-400 grit paper. Then wipe with wax and grease remover or isopropyl alcohol. Make sure the shit doesnít fall into the engine, I usually blue tape a little builders paper over the valve train just to be sure.

Itís not likely this will be the difference between whether it leaks at the end or doesnít, but if it DOES leak people will definitely ask if you did this stuff. So do it for your peace of mind :)