by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

Published 09/04/2017 at 07:20

by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

Published 09/04/2017 at 07:20

Tags: spit6

STARS: 7

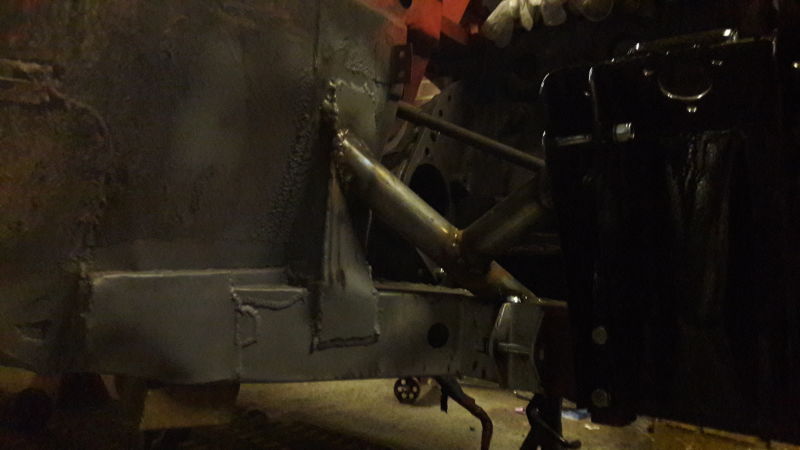

Mostly welded up one of the front suspension braces for my Spit. The idea behind these is that theyíll brace the front suspension towers and the chassis as it meets thefgn bulkhead, but in the event of a crash theyíll deform absorbing some of the impact.

If I just ran a straight tube back to the bulkhead, in a crash Iíd just end up spearing a weld-hardened shard of steel directly into my foot. Not something Iím particularly keen to do...

Also, proof that I can actually string together a non-blobby weld if I actually try ;)

"Trevor Slattery, ACTOR" (anacostiabikecompany)

"Trevor Slattery, ACTOR" (anacostiabikecompany)

09/04/2017 at 09:06, STARS: 0

So the body is now welded to the frame?

"tromoly" (tromoly)

"tromoly" (tromoly)

09/04/2017 at 12:28, STARS: 0

Youíre loading the tube in bending, never do that.

"MM54" (mm54mk2)

"MM54" (mm54mk2)

09/04/2017 at 15:19, STARS: 0

Thatís the point - itís stiff enough to brace the front frame rails but if he wrecks itíll bend the tube instead of spearing his leg.

"tromoly" (tromoly)

"tromoly" (tromoly)

09/04/2017 at 15:48, STARS: 0

Thatís terrible, over time the tube will bend due to cornering and general vibration fatigue loading the tube. Why not build longer braces that go above the shock towers and tie into a halo under the dash? So much stronger and safer in an impact, not to mention will actually provide stiffness.

"MM54" (mm54mk2)

"MM54" (mm54mk2)

09/04/2017 at 16:47, STARS: 0

Thatís a question for dr frankenstein.

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

09/04/2017 at 17:35, STARS: 0

Yep :) thatís been the work of a few months off and on. I thought about solid-mointing the body, but then read some articles about welding on plates to the chassis to strengthen it. Then thought Ďwhy not just weld the body to the chassis if iím going to be solid-mounting it anywayí. Did some (really) rough calculations and worked out that itíll be 112% (i think) stiffer from the one wall of the floor forming a box with the chassis, let alone all the rest of the structure. Then i thought i might as well weld the hardtop i had in place, and brace the front suspension towers. Then it let me go for a pretty radical rear suspension design which actually has a decent camber curve but cuts through most of the rear section of the chassis.

Can you see why this thingís taken me 4 years? ;) thatís just the project creep on the chassis!