by "JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

by "JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

Published 08/28/2017 at 19:28

by "JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

by "JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

Published 08/28/2017 at 19:28

No Tags

STARS: 1

Iím new to welding, I recently bought a 160-amp DC inverter arc welder and have successfully cobbled together a few things, mostly with 6013 rods. I have 1/16th, 3/32nd and 1/8 rods in 6013, and it seems very forgiving, my biggest problem being a tendency to let the slag get ahead of the pool and end up with nasty inclusions... in any case, as I understand it 6013, though easy to use and good for thin material, does not have very good penetration or overall strength, so Iíve been experimenting with 6011 and 7014... I only have 1/8 6011 and 3/32 7014... the 7014 seems quite nice, and Iíve been able to lay down some halfway decent looking beads with it, though the 3/32nds rod seems to leave a pretty anemic bead, maybe I should get some 1/8"? but Iím struggling to keep the 6011 from making huge undercuts and blobs :/ I understand that 6011 has deep penetration, but Iím having a lot of trouble with it... should I try a 3/32 6011? any hints?

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

08/28/2017 at 22:30, STARS: 0

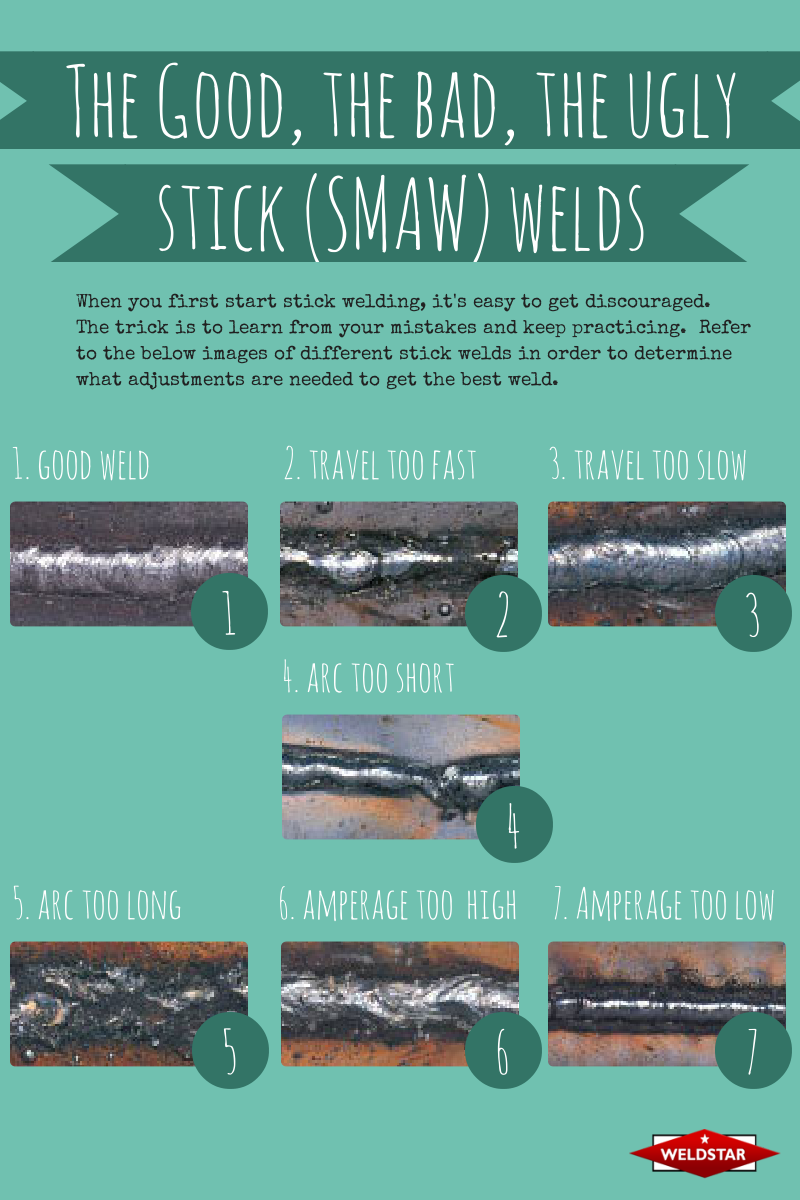

I normally end up welding with 1/8 7018s, but I also have made every single ugly weld on the chart, so in terms of better living through chemistry, I donít think I can help. Except... uh, 7018s work pretty good, and donít use cantankerous old semi-broken buzzboxes like I did starting out that canít maintain a consistent amperage? That, I guess.

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

08/29/2017 at 05:02, STARS: 1

Completely unable to offer any sort of stick welding advice as all my stuff is MIG, but it turns out you were bang on the money with my blobby welds being wire speed related.

I looked back at some older welds Iíd done and they were pretty pristine compared to the recent ones, and Iíve also noticed very recently that the wire keeps getting stuck if I hold the torch at anything approaching an angle so I think the ancient liner on the inside of the hose/tube thing has worn away so the wireís sticking.

Tested it just running it out while I watch and the wireís jumping all over the place. Tested the motor and that runs at a nice constant speed so I think itís getting caught in the hose and giving me a variable wire speed :S

Hooray! I might not be as naff of a welder as I thought ;)

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

08/29/2017 at 08:41, STARS: 0

Hooray! I might not be as naff of a welder as I thought ;)

The best part is that there seems to be a solution that doesnít require you to learn or unlearn anything. Thatís aces.

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

08/29/2017 at 09:06, STARS: 0

It absolutely is :)

I wonder if itíll be like replacing the lens on my welding mask. The previous one was fogged so badly that you canít actually see through it, so I noticed an immediate improvement in my welding when I could actually see what the hell was going on. Pretty certain itís made me a better welder as I was basically teaching myself to weld blind!

"I Will Always Be The Honey Badger" (iwillalwaysbethehoneybadger)

"I Will Always Be The Honey Badger" (iwillalwaysbethehoneybadger)

09/02/2017 at 13:47, STARS: 0

I second the 1/8" 7018. Iím a very amatuer welder, but as long as your metal is nice and clean it seems to produce the best results for me.