by "PartyPooper2012" (PartyPooper2012)

by "PartyPooper2012" (PartyPooper2012)

Published 08/07/2017 at 06:15

by "PartyPooper2012" (PartyPooper2012)

by "PartyPooper2012" (PartyPooper2012)

Published 08/07/2017 at 06:15

No Tags

STARS: 0

Friday night, hooked up the trailer to the truck so I can get some yard waste out to recycling center. Was a bit dark. Couldn’t really see all that well, but I hooked it up as I did many times. Tongue dropped on the ball like it does. Locked it all up. Chained up. No problem.

Next morning I go to tow it. Pull up to a light. BANG. Loud noise and a jolt from the back. WTF? Well, no one rear ended me so whatever... maybe trailer did some trailer crap back there. Still on, so keep trucking. Only 2 blocks to go.

I get to recycling center and see that the damn tongue had slipped off the ball and rammed into the tow hitch receiver and bent the tongue good enough so it won’t go back on the ball. Fuck.

It rested on the ball passed where the hook up would be. So I dragged the damn thing slow and careful. Waved to all the cops. No one got killed.

Now I need to cut off the old bent tongue and weld a new one on.

All I have is a mig welder and zero experience welding. If I get enough welding practice to run a pretty bead that will hold tight, should I proceed, or should I find someone who can weld with a stick. Is there a strength difference between mig and stick?

I don’t trust myself with this task due to lack of my experience and heavy weight and lives it will involve risking, so I know I will take it to a guy near me to weld on a new tongue. You don’t have to worry about me trying to be a cowboy and welding it half assed myself. That isnt going to happen. The question is strength wise. Is a stick stronger than mig in welding or is same?

"pip bip - choose Corrour" (hhgttg69)

"pip bip - choose Corrour" (hhgttg69)

08/07/2017 at 06:52, STARS: 2

try it and find out, if we never hear from you again, we’ll take it as a sign it didn’t go to plan

;)

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

08/07/2017 at 06:55, STARS: 2

but then who would poop on your parties?

"MasterMario - Keeper of the V8s" (mastermario)

"MasterMario - Keeper of the V8s" (mastermario)

08/07/2017 at 07:41, STARS: 2

PartyPooper2020?

"EngineerWithTools" (engineerwithtools)

"EngineerWithTools" (engineerwithtools)

08/07/2017 at 07:58, STARS: 4

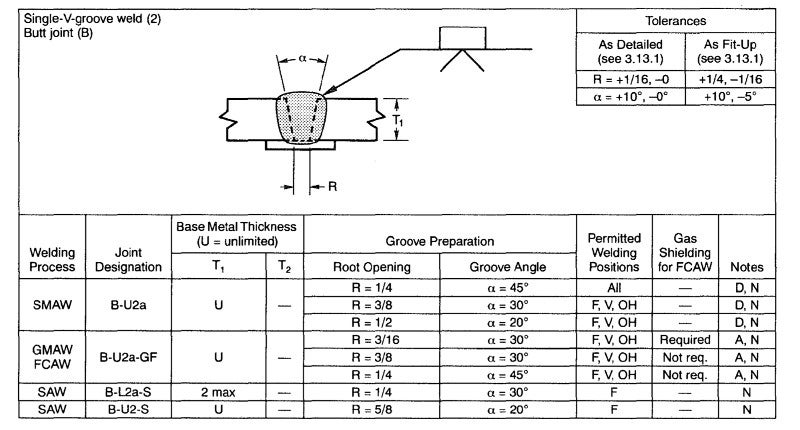

It depends on the joint design and rod/wire spec much more than the method. MIG is generally easier to get a nicer-looking weld, but a good welder will make art with any tool.

Anyway, for a trailer, the biggest concern is fatigue strength, which means good joint prep, the best possible weld, done in-position, and if at all possible, some reinforcement. Assuming it’s some kind of butt connection, a groove weld is appropriate, done with a backer bar. Something like...

"KevlarRx7" (kevlarsupra)

"KevlarRx7" (kevlarsupra)

08/07/2017 at 08:01, STARS: 3

Find someone who can already weld, with liability insurance.

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

08/07/2017 at 08:14, STARS: 1

Ugh! That fucking guy. He’s not trust worthy. Sometimes he poops. Other times not really.

"MasterMario - Keeper of the V8s" (mastermario)

"MasterMario - Keeper of the V8s" (mastermario)

08/07/2017 at 08:17, STARS: 1

What about PartyPooper2016? I hear his poops are huuuuge. The best poops. The greatest in fact.

"sn4cktimes" (snacktimes)

"sn4cktimes" (snacktimes)

08/07/2017 at 08:28, STARS: 3

Agreed. Welding method here is less critical than the joint size, prep, and weld size. I modified my grandfathers hitch a few years ago as he couldn’t find what he needed. Did a full-pen weld, with some pre-heat, with 1/16 flux-core with shielding gas, back gouged the far side and welded it back up. So was all new and “sound” weld metal. Had it mag-particle and ultrasound tested for free the next time the inspector came to the shop. All good. It was similar prep to what you’ve shown, minus the backup bar. Used a 1/8 root face on both sides and no gap, hence the back gouge. Worked great and he’s never had an issue with it.

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

08/07/2017 at 08:42, STARS: 0

Yeah. He’s good. But he’s not running for office. I’ve been asking him to run, but he has no interest

"Quadradeuce" (quadradeuce)

"Quadradeuce" (quadradeuce)

08/07/2017 at 09:17, STARS: 1

DO NOT FIX THIS ON YOUR OWN! Trailer hitches should be fixed by a pro. It’s not worth risking an accident, especially since accidents that involve loose trailers end up being petty nasty. We had a fatal one happen around here that killed a young college girl on her way home from work. Home bodged hitch let loose, trailer flew across median and struck car at freeway speed. Just get it fixed properly.

"EngineerWithTools" (engineerwithtools)

"EngineerWithTools" (engineerwithtools)

08/07/2017 at 10:13, STARS: 0

Exactly! If you can get to both sides, back-gouge is a little cleaner (eventually... it starts by looking uglier).

You make a good point: Preheat and a controlled cool-down, even when not required, helps!

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

08/07/2017 at 10:42, STARS: 1

see.... title... I already knew you were going to say that. I am not going to fix this myself. I am too paranoid of things that might potentially go wrong.

I just wanted to know if there is difference between molten metal from mig or stick welder. My guess - no.

"Quadradeuce" (quadradeuce)

"Quadradeuce" (quadradeuce)

08/07/2017 at 11:38, STARS: 1

I know, but since I have seen the results of home welding a trailer hitch, I like to broadcast a PSA when the chance comes up. Knowledge is power and all.

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

08/07/2017 at 11:41, STARS: 0

yeah. once the “professional welder” is done with it, I am still on my own. No guarantee his weld would be better than mine.