by "RamblinRover Luxury-Yacht" (ramblininexile)

by "RamblinRover Luxury-Yacht" (ramblininexile)

Published 06/23/2017 at 10:35

by "RamblinRover Luxury-Yacht" (ramblininexile)

by "RamblinRover Luxury-Yacht" (ramblininexile)

Published 06/23/2017 at 10:35

No Tags

STARS: 1

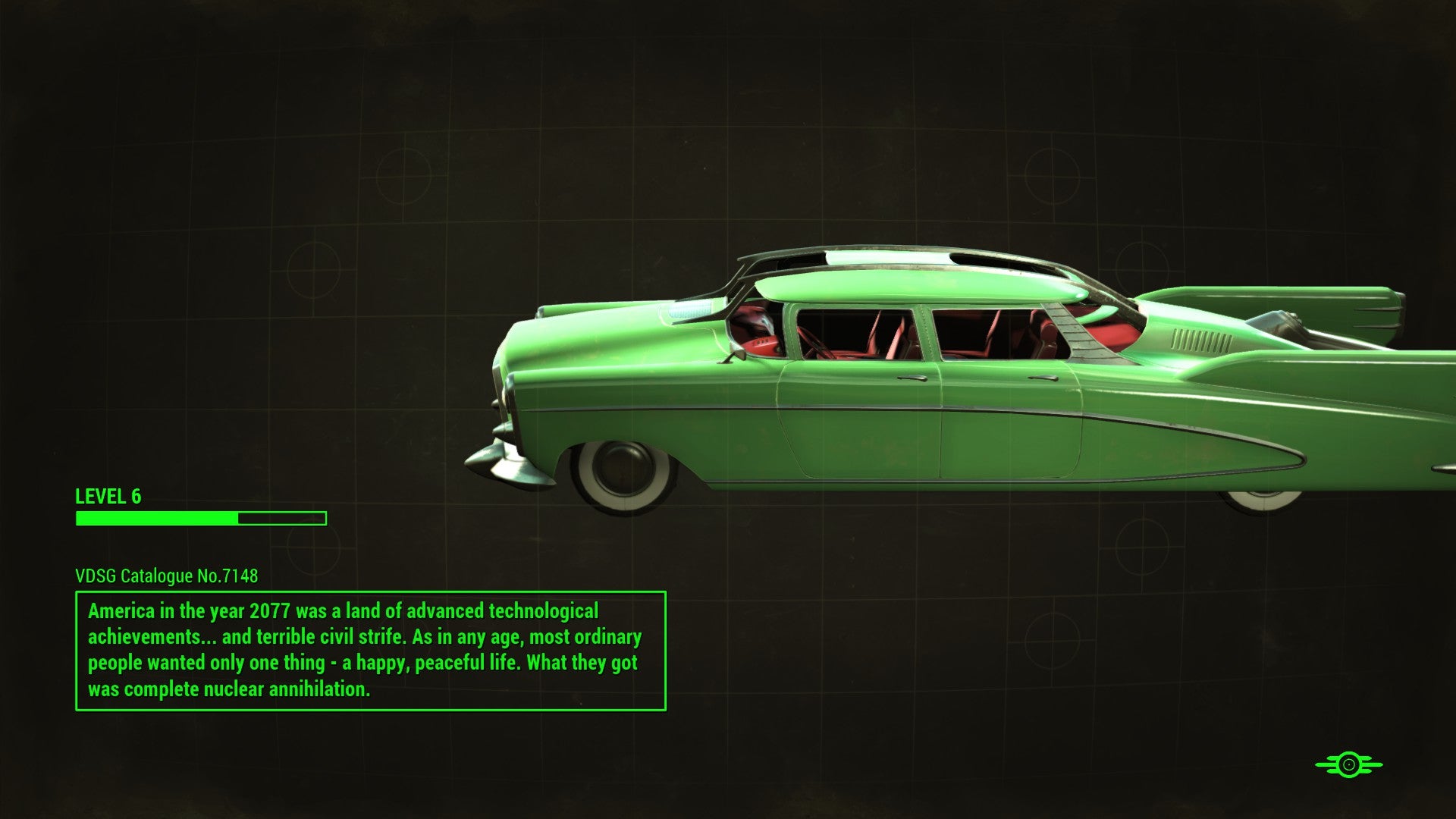

Prop cars. All this time learning body panel techniques, fascinated with customs, love of unique cars, engineering and sheet metal background - why am I not doing that?

"LongbowMkII" (longbowmkii)

"LongbowMkII" (longbowmkii)

06/23/2017 at 10:47, STARS: 1

not many people pay money for that

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

06/23/2017 at 10:52, STARS: 0

True. I think the tricky part would be threading the needle between the custom market and customers for props that would be legally okayed to have a prop car related to a specific IP. If the IP owner okays prop cars or commissions them, it’s one thing.

Then again, there are IP-related hobbies that bring in a lot - mostly in cosplay/costumery, but there are well-established prop companies selling *mostly* to fandom, like several for weapon props. Some of which props go for thousands. Also, a lot of official IP recognition/commissioning tends to follow independent work in an area, like Stormtrooper and R2 prop work with semi-official recognition. The old “creating the market for a product” trickiness.

"Jake - Has Bad Luck So You Don't Have To" (murdersofa)

"Jake - Has Bad Luck So You Don't Have To" (murdersofa)

06/23/2017 at 14:46, STARS: 0

The word ‘prop’ has lost meaning suddenly

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

06/23/2017 at 14:47, STARS: 0

!!! UNKNOWN CONTENT TYPE !!!

"Die-Trying" (die-trying)

"Die-Trying" (die-trying)

06/23/2017 at 15:28, STARS: 1

did somebody say PROP cars??............ the hard part about actually building fun prop cars, would be finding the fun iconic looking sheetmetal off of cars, and then cutting them up....... think of the late 50s kustoms.

the ones that were a collection of sections of off 5 or 6 cars....

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

06/23/2017 at 15:42, STARS: 1

I’m thinking the easiest thing would be to form the simple sections that have to be strong on a readily-come-by frame structure, let that give a core to the arrangement, and do a lot of the big curves in fiberglass. Use a donor or donors where appropriate (particularly for a 70s-90s prop car), but don’t get tied down - otherwise you’re making an Excalibur or something that looks obviously pieced.

I’m thinking the biggest part of it, actually, is doors, glass, and glass frames. Custom glass is a big enough trick all its own that you could run that as the main business and run film and convention props out the side - and if you put unique doors and windows on a firewall that nobody will ever see and get good at optimizing for fiberglass wings and hoods, you just need to do steel for fascias and things and you can make a car that looks like literally anything on an existing pan.

Just work up a really good die system for curved glass and a good die system for door blanks and skins, and you’ve got it made.

"Die-Trying" (die-trying)

"Die-Trying" (die-trying)

06/23/2017 at 16:00, STARS: 0

its that “making something that doesnt look like it is obviously pieced” that would get real tricky...... that and turning them out fast enough to be practical.......

i been thinking about building “SHOT RODS”(hot rods that look to be just past thier prime) myself.......

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

06/23/2017 at 16:08, STARS: 1

What I’ve thought about is how hard it would be to build low-tolerance CNC hardware for lost foam shaping, do aluminum casts, maybe a surface treatment(!) and using aluminum body dies (!).

An aluminum body die wouldn’t hold up that well for over a dozen or so stampings, but with the required CNC hardware for a foam pre-panel only having to be accurate to like 1/8" for anything without a deep draw process in it, you could have your home-made CNC bulldoze a whole panel out of a foam block in a matter of a half hour, cast in another hour and a half, and smooth the aluminum positive and negative with a sandblast + hand smoothing within the day. Et voila, a whole body panel die, and much easier than an oak forming die and hammer work.

"Die-Trying" (die-trying)

"Die-Trying" (die-trying)

06/23/2017 at 16:20, STARS: 0

that would be outright pumping them out, at that pace......

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

06/23/2017 at 16:26, STARS: 1

A day to draw up a firewall, two days for inner and outer door panels, flip them for the other side, use off-the-shelf regulators and other parts, and each major sheet metal piece to make in about a day, with only about one man’s labor and a few tens of Gs of hardware.

It’s a dream that I have here, but it’s not an impossible one.

"Die-Trying" (die-trying)

"Die-Trying" (die-trying)

06/23/2017 at 16:33, STARS: 0

incredibly reachable dream....