by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

Published 05/03/2017 at 19:10

by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

by "BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

Published 05/03/2017 at 19:10

Tags: spit6

STARS: 2

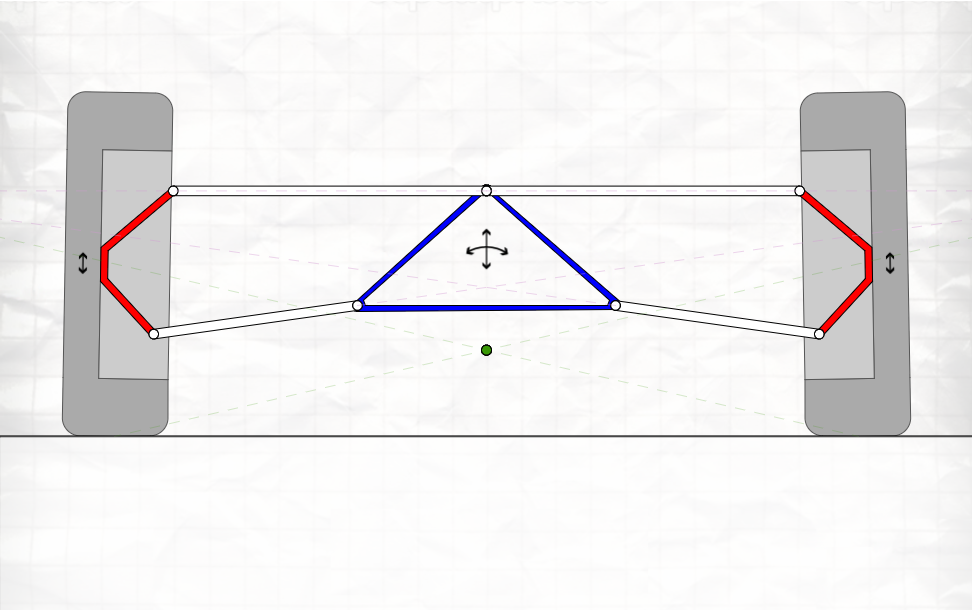

Well, the last few hours of it not spent at work at least. Stuck my Spitfireís rear suspension into an online model and measured how stuff like the roll centre and camber changes in roll and compression. All of the compression stuff is near as damnit the same as my wooden mockup :)

The dynamic roll centre looks pretty good too, as does the camber change in roll (a little in excess of the body roll right up to 2.5 degrees where it levels off to match body roll).

Itís all shaping up rather nicely :)

Add onto that I replaced an ABS sensor on the E46 which banished the last of the lights on the dash, and I got the Citroen up into the air and found the point where itís leaking substantial quantities of hydraulic fluid (a little t-piece on the return line which has split in two).

Not a bad day all told :)

Hereís the model if anyone wants to play around with it :)

!!! UNKNOWN CONTENT TYPE !!!

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/03/2017 at 19:19, STARS: 1

Sorted, then. Iím behind on everything, meself.

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

05/03/2017 at 20:01, STARS: 0

Sort of :) still got to build the thing yet. Iíve got a jig sort of on its way. Just waiting on a metal-cutting chop saw so I can get nice 90 degree cuts in tube and I should be in business :)

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/03/2017 at 20:37, STARS: 0

Iím probably a month from getting a proper sheet metal brake, which Iíll need for the fancier bits of the Rancheroís roof and the repair of the Galaxieís trunk. This blighter:

https://www.summitracing.com/ga/parts/hck-wfbp4816/overview/ †

Best affordable through me picking it up in McDonough, GA - a mere four and a half hours away - as it would otherwise be some $150 to get here. Of course you already know Iím mad for long driving trips, but I have a friend in the area I visit pretty routinely, so itís not even a long trip for nothing else. Plus, an excellent Korean supermarket...

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

05/04/2017 at 05:02, STARS: 0

Sweet! Iíve been thinking of how to make one of those actually. Need some really beefy steel and some snug-fitting sizeable CDS tube to make hinges from. Itís on the list of things to do, but without somewhere to put it at the moment itíll have to wait.

Am I reading it right that itíll only do up to 16g (~1.2mm) on the 48" one? Or is that up to 16g on the full 48" length, but thicker steel of shorter length?

Most of my work is on 1mm stuff, but I make a fair few brackets from 2mm and 3mm steel, and Iíd be pissed if Iíd spent circa $600 on something thatíll only bend 1mm steel...

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/04/2017 at 08:54, STARS: 0

In theory, it might well do over 16GA on shorter things, but itís not really meant to. The big point at which these encounter weakness is with flexing away from the workpiece in the center, and each additional .5mm or so increase cost astronomically, as well as the weight of the machine. That one is actually unusual in being able to handle 16GA over its full width in that price range. It could likely handle 2mm if no more than a foot long and toward one side, but it would depend. That sort of thing I would tend to leave to vise and/or torch work, however.

Thereís actually a brake in the shop already, 48" long... but itís rubbish. Homemade, and not rigid enough in the center, not to mention not having removable fingers for box braking, nor a sharp enough edge on the main finger it does have. Not even well suited for half mil stuff.

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

05/04/2017 at 10:08, STARS: 0

Ah gotcha, yeah weíve got a cheapy vice-mounted one that has that problem. Lifting in the middle.

I suppose the way to do it DIY is to get some really, thoroughly beefy box section to make the finger out of. Something thoroughly industrial in scale. Iíve got a left-over roofing I-beam that might help there. Could have it on a geared crank handle or something to cope with the weight :)

Agreed that a vice and a blowtorch is probably the best option for thicker stuff anyway, and the pipe bender for anything even thicker than that ;)

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/04/2017 at 10:29, STARS: 1

The finger for the homemade one weíve got is something like a 5"X3" angle with 3/16 or 1/4" webs, but it still flexes, and the gate/tongue on it is lighter and therefore worse. The forces are incredible. Itíd do better if I were to mill the edge of the angle for a sharper bend (and less force for a given fold), but since I dontí have a mill yet... At any rate, thatís why you see heavier brakes going for heavier and heavier tongues and more extensive cross-bracing above the finger, to the point if becomes quite ridiculous.

https://www.magnumtools.com/products/8160-tennsmith-8-foot-x-16-gauge-manual-straight-brake-hb97-16/

http://www.penntoolco.com/hbt48-12/

Note that the 12GA four-footer has similar end hardware to the eight-footer and costs *even more*. Note also that the capacity of the four footer with the support angle removed drops all the way to 16GA.

Iíd really like to have a Tennsmith pan brake and shear, but unless something crops up uncommonly cheap, thatís not in the cards. They make a much better brake than the Summit option, but at $4400 for the pair.

Iím currently in a shop with a 10' air-driven shear capable of 11GA - I believe a new replacement would be some $40,000 - and a multi-hundred ton press brake worth at least as much, but itís simply not practical to drive ten minutes over to the shop, spend ten minutes switching things on, bring in steel, set the shear backstop and shear, apply force and flange settings in the press brake computer, adjust the back stop width, put in enough width in dies, and finally fold the piece. Then, pack all that back down again, switch things off, drive back - total time, probably something like an hour and a half for a piece I mightíve miscalculated.

Mark me down as one for a manual pan brake, then. If I need a brake (and not vise) for 11GA, then the best option would likely be to get a small press brake adapter for the bench press, as that *and* a 48" 16GA model is wildly cheaper than a 48" brake for 11GA.