by "functionoverfashion" (functionoverfashion)

by "functionoverfashion" (functionoverfashion)

Published 05/01/2017 at 15:03

by "functionoverfashion" (functionoverfashion)

by "functionoverfashion" (functionoverfashion)

Published 05/01/2017 at 15:03

No Tags

STARS: 0

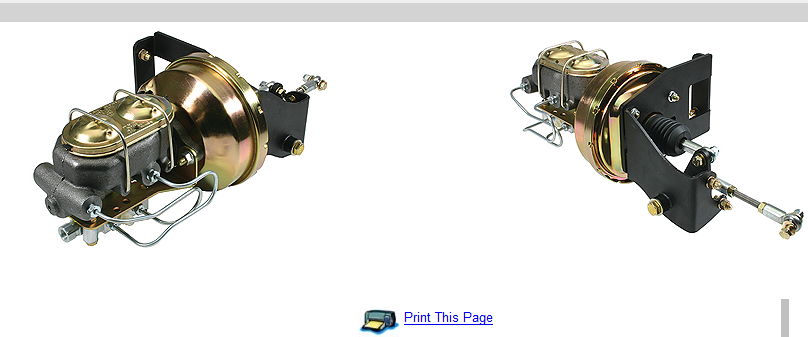

http://www.classicperform.com/Store/1948_64_Ford_Truck/4852BBD.htm

In researching options to convert my 1961 F100 pickup over to a dual master cylinder, this came up as an option.

The truck has a factory single reservoir brake master cylinder and for safety reasons I want to upgrade to the dual. Iíve been on the forums and asked some local Ford Gurus about this kind of thing, and basically thereís no single bolt-on solution. One problem is stroke length of the MC piston. The brake pedal is set up to push the factory MC some length that is likely to be shorter than what is required for full activation of the dual MC in the event of a failure. Mind you, it would work all the rest of the time just fine BUT the whole reason Iím doing this is for an added layer of safety in the event of a failure, so there you have it.

The kit in the link/image I posted includes everything you need to make this work, including an adapter bracket to bolt up to the firewall, and it sure looks like it has a little bit of linkage trickery to make up the distance in throw from the stock pedal assembly to the dual MC. The product description mentions this specifically, and it even uses the same MC (from a Corvette) that the guy at my local shop said he used on his M715 when he upgraded THAT to a dual MC. Coincidence? I think not.

So my question here is, does anyone have experience with either a) Classic Performance Parts out of Placentia, CA - or b) know of a reputable source for a product/kit like this? or c) maybe youíve got a better idea.

The reason Iím leaning toward spending $300 on a kit rather than sourcing various other parts and bolting it all up is that the time and effort involved in patching this system together could quickly exceed the peace of mind and simplicity of getting this kit. I still have to make up new brake lines to separate the front and rear circuits, but this seems like a series of headaches solved instantly. Maybe.

I appreciate any input you all might have. The Ford forum guys, while highly knowledgeable, generally lean toward sourcing parts individually. But Iím waiting to see if they chime in on this particular kit... the kit idea came from one of them in the first place.

Pic of the truck in question, alongside its new friend, for your time.

"crowmolly" (crowmolly)

"crowmolly" (crowmolly)

05/01/2017 at 15:12, STARS: 1

does anyone have experience with either a) Classic Performance Parts out of Placentia, CA

Yes. I own some of their parts as do a number of people I know.

Mostly decent stuff. I have a master/booster combo and itís OK. Something kind of wonky with pedal slop but it hasnít effected brake performance. Iíd consider them to be a Professional Products vs. an Edelbrock in the industry.

A few years ago people were reporting issues with suspension components (ball joints) failing, and I donít particularly care for their use of nylock nuts vs. castle nuts for ball joints.

"Nothing" (nothingatalluseful)

"Nothing" (nothingatalluseful)

05/01/2017 at 15:16, STARS: 1

I just finished the brake job/upgrade on the Cougar. I didnít go power, though. I didnít use a kit, but there were times I wish I would have. It wasnít difficult sourcing the parts, but I didnít even think about the adjustable pushrod for the MC until I got installing the MC. Díoh. Thereís something to be said for the convenience of a ready made kit for exactly what youíre trying to accomplish.

Iím not familiar with that vendor, though.

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/01/2017 at 15:18, STARS: 1

That cylinder+ booster setup is the same one that Speedway and everybody else sells, for a reason - itís simple, and it works. Not just for old Ford trucks, but almost every hot rod with a generic booster/cylinder conversion in existence ends up using that if itís short of a custom tailored Wilwood setup. Throw is as you note, however - not quite as simple. You need to pump the same volume of fluid for a given amount of travel to your front brakes as before, and if your original cylinder was the same diameter, youíd be pumping ~50% more to your front brakes with the same stroke, because the dual cylinder (at least in theory) consists of two stages operating at that distance at that diameter. Full volume for front and rear now operating front only, with typical front volume being about 2x rear, that equals 150% for the same amount of travel.

But: a dual cylinder requires internal support for the second stage. Usually. So the actual displacement of a cylinder of given diameter is different. On a lot of vehicles with a single master, the travel is really far, but itís possible (if the diameter is large enough, popular on Fords) for the travel to be less than a smaller diameter dual cylinder because the main diameter is so stinkiní huge.

That appears to be the case with this conversion. Unlike the conversion Iíve had to plan for my younger brotherís Land Rover, in which the new master will have about 25% shorter travel with a 1" dual than the original 1 1/8" Girling ďCompression BarrelĒ single stage master.

"Rust and Dust - Oppositelock Forever" (rustanddust)

"Rust and Dust - Oppositelock Forever" (rustanddust)

05/01/2017 at 15:26, STARS: 1

CPP is a pretty reputable company. Iíve ordered from them on a few different classics weíve had in the shop, and theyíve always treated me well.

Another resource you may not be familiar with for that truck is Dennis Carpenter. Iíve ordered a ton from them for a Ď66 F100 weíve done, and a Ď65 thatís in process now, and theyíve always had quality stuff and excellent service.

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

05/01/2017 at 15:27, STARS: 0

So you could figure the amount of travel given by the geometry of how the pedal is hung and adjust by choice of MC piston diameter?

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/01/2017 at 15:36, STARS: 1

The simple answer for pedal travel being made right is to match the limit to limit travel on the new cylinder to the limit to limit travel on the pedal mechanism/old cylinder. That will at least mean the cylinder is put through a proper range of motion. Moving the right amount of fluid is something you can afford to miss *slightly*, because a correctly functioning set of drums doesnít require much slack to auto-adjust, and discs will bleed back about the right amount that they need to for release. Of course, the easiest cheat is to look at a later version of the carís family with shared parts - if it has the same sized components at the wheels, its full range of travel is properly sized and the only thing that remains is to match the ratio.

In the case of my Land Rover example, I know that the Corvette style dual master is sufficient because itís the same diameter as the Rover dual master on later models and has a *longer* range of motion - therefore, even being perhaps smaller than the original single, it still pushes more than enough fluid.

"functionoverfashion" (functionoverfashion)

"functionoverfashion" (functionoverfashion)

05/01/2017 at 16:53, STARS: 0

Thanks for the detailed response. I think what Iím finding is that the single MC that was stock probably has a shorter throw than a compatible dual MC but Iím also not totally sure about that. It seems like the kit has accounted for this difference with the extra linkage, allowing the stock brake pedal to remain unmodified.

The issue Iím hoping to avoid is that, in the event of a brake line failure or something, the dual MC doesnít do any good (over a single) unless the piston can be moved its full travel length, if that makes sense... I suspect you know what I mean Iím just not explaining it that well. I think there is a wide variety of dual mcís for drum-drum setups that will move enough fluid for my application....

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

05/01/2017 at 16:59, STARS: 0

My case is the Ď71 GMC van. No vacuum assist... But they made that van for 24 years, so there might be answers from later years..

One of the things Iíd like to do with that van is convert the rear axle suspension from leaf spring to something more sophisticated, like maybe a four-link arrangement. Add power steering and air conditioning...

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/01/2017 at 17:04, STARS: 0

Your worry is that with the shorter throw, the fluid displacement of the single stage would be less than the fluid displacement of a single, and thus not enough to achieve stopping? You neednít worry. If it will stop your car properly without leaks (adequate fluid to all cylinders), it will stop your car with a leak unless multiple leaks are present front and rear. The fluid required to stop your front wheels only or your rear wheels only will not change in the case of a leak on the other circuit, so if it will stop normally, it will stop, regardless whether the cylinder is capable of pumping as much fluid total.

In fact, because the sweep of the piston is longer than stock, itís very possible that the cylinder can keep up *better* with a leak on one of the circuits because it can valve more fluid through itself rapidly with the longer range of motion. It may also be easier to bleed due to better pumping, even if individual strokes donít pump *quite* as much as a single pumping all its fluid to *one* cylinder would.

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/01/2017 at 17:11, STARS: 0

If youíve got front discs, the applications guide for the caliper shows use up to Ď76 in a variety of models. Since the front brakes would drive the capacity calculation most... at any rate, itís quite likely that the power master for one of the other models would be perfectly sufficient - something like an F-body booster and master. Particularly since master cylinder linkages and mounting patterns are very freely repeated - my compact Falcon and full-size Galaxie share the same setup for the master in most respects.

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

05/01/2017 at 17:47, STARS: 1

No vacuum assist, though.

"functionoverfashion" (functionoverfashion)

"functionoverfashion" (functionoverfashion)

05/01/2017 at 19:16, STARS: 0

The concern that was voiced on the forums was that the shorter throw of the brake pedal wouldnít be enough to activate the secondary circuit on a failure. Someone linked a youtube video on this, which I thought was pretty well done and explained the issue. I canít access the forum right now for unknown internet reasons. Maybe the video is inaccurate, it does generally describe disc setups while mine is drum/drum.

The basic principle though, was that if you have a pedal that is designed to move a piston 1" and only 1" with the full travel of the pedal arm, and the dual MC can travel 1.5" then if one circuit fails, you might hit the floor with the pedal before the secondary reservoir is pressurized enough to work.

Iíve had brakes fail on a Ď72 F100 which had a dual reservoir, and I had no brakes at all after the initial brake line failure which was a rear line. I still donít know exactly why that is, but it just shows that dual MCs arenít fool proof, and it makes me want to be very sure Iíve got my ducks in a row since Iím messing with the system anyway.

Thanks for the continued discussion, this is why I came here... more opinions are good!

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/01/2017 at 21:44, STARS: 1

I had to do some review myself, as Iím used to dual masters that donít have a lot of ďequalization spaceĒ and/or have more positive connection than normal, but you would seem to be right - to a point. Reduced pumping *is* a thing, and I was somewhat wrong. If an MC has a *lot* of space between the two circuit pistons, then it can take a lot of travel for the first piston to push on the second piston sufficiently or the second piston to stop close enough to the top to let the first piston work. In your case of total loss, itís possible your front brakes werenít adjusted up tight enough for the (reduced) pumping volume to do the job. Anyway, as I was saying to OC, there are other reasons to make sure that the range of motion is a pretty good match as well, like permitting fluid pumping, so leaving it at 1"/1.5" - probably a bad idea, but 1.25"/1.5" would probably be close enough, that sort of thing.

tl;dr: I completely forgot about the extent of the floating relation between the two pistons and was dumb.

I have just conducted some research on Ford ďjam jarĒ masters as you have, because I thought ďhey, maybe the Mustang cylinder would be workable somehowĒ. Because the Falcon/Mustang brake pedal setup is very similar, and thereís a bolt-up dual jam jar replacement for those. Nope. The problem is exactly as one would surmise - .81" piston travel vs. 1.20", so despite bolting up, a dual replacement for a Falcon/Mustang/Galaxie/Fairlane/EVERYTHING jam jar will not fit a truck. Because of reasons. If you donít mind drilling a hole, however, I might have a solution:

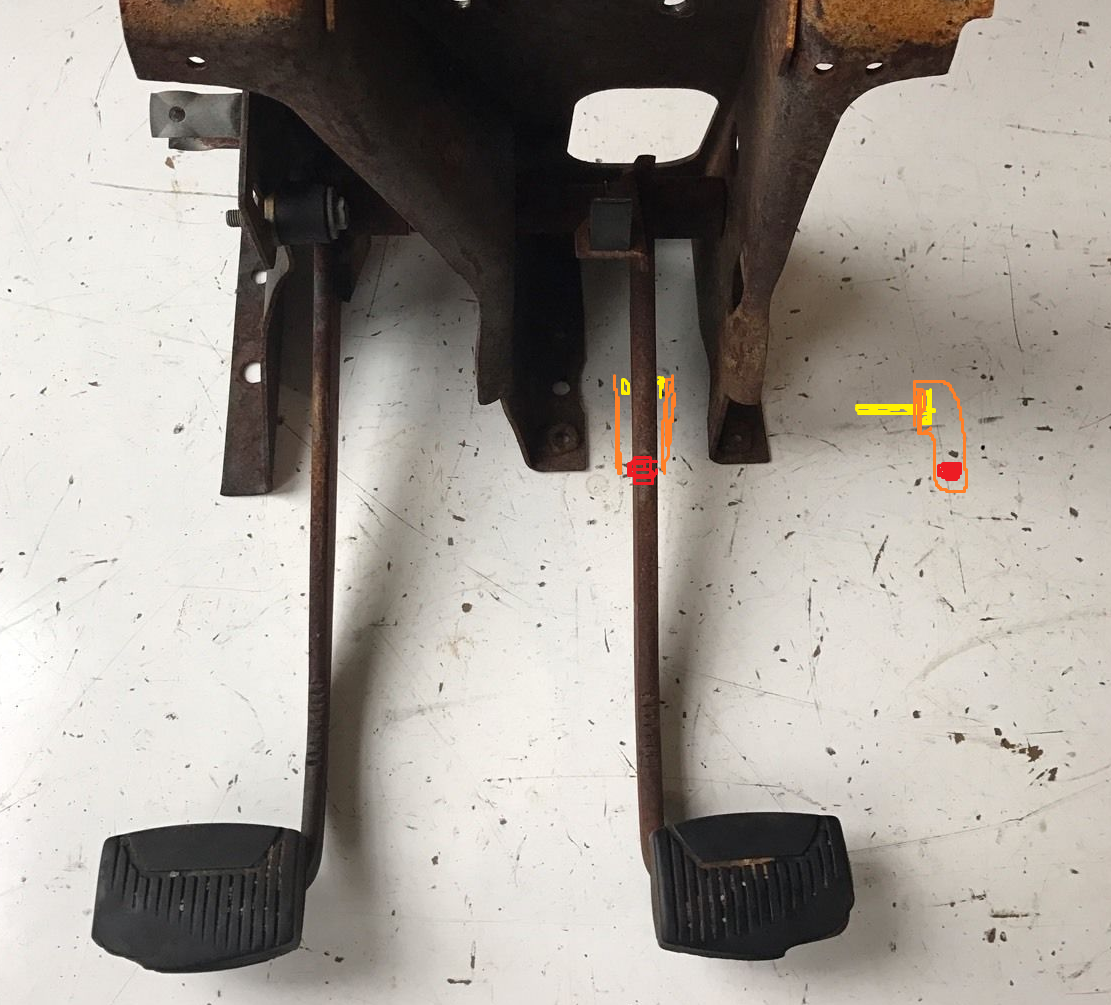

Here is a picture of your pedal setup, with the attachment point of the pushrod indicated with the red doodle. What you need is about 50% further travel, and then any and all dual masters will work - right?

If you make a small bracket that moves the rod attachment point (red) about 50% further down the pedal lever, and then (importantly) fix that relation to the pedal pushrod, you can use the stock mounting location (possibly with a spacer), thread your little bracket onto the pushrod, and go on your merry way - with less space taken up under the hood and a more stock look, and only a bracket to make and a master cylinder to buy.

Of course, this does change the line of action somewhat and might make the action less smooth. Itís a thought, though.

"functionoverfashion" (functionoverfashion)

"functionoverfashion" (functionoverfashion)

05/02/2017 at 09:45, STARS: 0

Wow, thanks for the all the detailed discussion - seriously, this is extremely helpful. I like your bracket idea on the pedal arm itself, but I still want a booster, so Iím looking at a big bulgy thing under the hood pretty much no matter what.

I completely forgot about the extent of the floating relation between the two pistons

Thatís basically what I learned from the video about the internal workings of a master cylinder. It doesnít seem to me like itís the best setup, intuitively. Seems like it would be better if you didnít have to nearly put the pedal on the floor to get braking pressure in the event of a line failure.

In your case of total loss, itís possible your front brakes werenít

adjusted up tight enough for the (reduced) pumping volume to do the job.

I also wonder, in hindsight, if I had pumped the pedal some more if I could have gotten some braking. But I had to immediately dodge multiple other vehicles, trees, and a ditch, so I didnít even take my foot of the clutch (both feet in!) before it was all over and I was back on the road, coasting to a stop safely on the road side.

Hereís the youtube video in question, Iím putting it un-linked because kinja.

youtu.be/bGKJOICWmFQ

This is the forum thread where I revived an old thread to ask my question, and another discussion someone linked me to...

https://www.ford-trucks.com/forums/1092164-need-dual-master-cylinder-kit-2.html

https://www.jalopyjournal.com/forum/threads/need-1-stroke-oem-master-cylinder-help.83063/

"functionoverfashion" (functionoverfashion)

"functionoverfashion" (functionoverfashion)

05/02/2017 at 09:46, STARS: 0

I love it! What year is that truck? Can I see the rest of it?

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

"Rusty Vandura - www.tinyurl.com/keepoppo" (rustyvandura)

05/02/2017 at 09:55, STARS: 0

www.tinyurl.com/vandurapics

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

05/02/2017 at 10:43, STARS: 1

If thereís a booster that bolts up to the ďjam jarĒ pattern, then it would work fine if you can get the throw situation fixed. On the other hand, back on the ďworks well even if throw isnít perfectly fixedĒ, thereís the option of using a parallel cylinder:

A 3/4" bore in parallel with a 7/8" bore (so about a 3:2 fluid displacement ratio - not quite 2:1), with a heim in between to let them develop equal pressure without compromising *everything* when you lose one circuit. Downside - would be nearly impossible to rig for power.

I totally get you on wanting to go for power when you have the chance, though.On the *other* other hand, if youíre open to making brackets/moving things for a power master (because a booster will likely not mate up to the two-bolt jam jar mount pattern) and open to drilling *a hole* through the firewall as well as the one on the pedal stem, and if you can move the booster down on the firewall ~2", you could just (effectively) move the booster down to where you get the right amount of travel. Simple.

Also, because I am a wizard, unless I am reading my source wrong I was able to figure out that the ďcorvette styleĒ cylinderís normal stroke length is 1.66", which is even worse than the Ford dual drum style. Less and less of a surprise that that conversion nearly doubles the throw - it has to!