by "bhtooefr" (bhtooefr)

by "bhtooefr" (bhtooefr)

Published 04/24/2017 at 12:18

by "bhtooefr" (bhtooefr)

by "bhtooefr" (bhtooefr)

Published 04/24/2017 at 12:18

Tags: planelopnik

; d-motor

; flathead

; sidevalve

STARS: 4

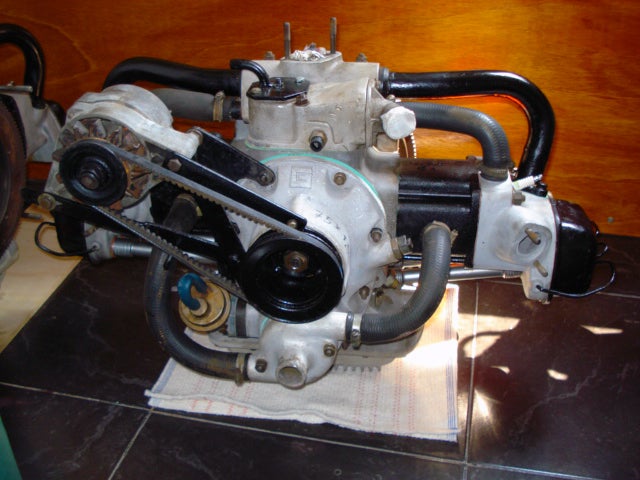

This is the D-Motor LF26, a 2.7 liter (they seem to have trouble with displacements corresponding to model numbers, the first-gen LF26 was a 2.5 liter, and the upcoming third-gen will be a 2.9 liter) flat-4 aero engine.

Itís aimed at light sport aircraft, making 91.8 hp @ 3000 max power, 88.8 hp @ 2800 max continuous power, on just about whatever fuel you can throw at it. Their biggest competition would be the Rotax 912 family, a 1.2 or 1.35 liter engine with watercooled heads, aircooled cylinders, at 80 or 100 hp @ 5800 depending on displacement - note that the higher RPM of the Rotax requires reduction gearing for the propeller. The Rotax is lighter in carbureted versions, but the D-Motor engine is fuel-injected, and the fuel-injected Rotax†912 iS (also 100 hp @ 5800) is heavier.

Thereís also a flat-6 variant thatís under development - basically the same thing, but two more cylinders.

Thereís a couple things, though, that are odd about this one. First off, note that thereís no cooling fins - this oneís entirely watercooled. Typically, airplane engines are aircooled for weight and simplicity reasons (and the Rotax 912 family only watercools the heads), but there are reasons to watercool - better capability to handle varying power levels without having to worry about thermal shock, for one. And, if you could get watercooling in, that can help stabilize the combustion behavior.

But, thatís not whatís really weird - the really weird part is that itís a flathead - aviation engines are usually overhead valve with pushrods. Apparently, they decided that the low RPM operation meant that the negatives of a flathead (poor breathing, poor combustion chamber shape) were reduced, and it greatly reduced weight and size. Reduced weight meant that there was the ability to watercool it without excessive weight, getting the benefits of watercooling (and in turn reducing more of the flatheadís negatives), and reduced size meant that they could get more displacement in a small enough package to fit into tiny LSAs (enabling decent power at low RPM).

Fuel consumption looks like itís a bit higher than the Rotax 912 iS, but significantly lower than the carbureted 912s. (And, simplicity is sometimes worth spending some fuel on to ensure reliability - look at all the huge displacement pushrod aircooled flat-4s in the aero space.) Looks like price is right in between the carbed and the injected Rotax engines.†Itís certainly interesting to see a new flathead existing in 2017, though, thatís for sure.

Now, I should probably work on that state of flat-4s in cars article...

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

04/24/2017 at 12:46, STARS: 0

Neat!

such a compact and clean looking little engine

Makes sense and packaging is always a huge factor. Of course now to really take advantage you really want a plane designed to house that smaller form factor engine. Or maybe the space savings is already being taken up by the extra footprint for the displacement.

"WilliamsSW" (williamssw)

"WilliamsSW" (williamssw)

04/24/2017 at 13:08, STARS: 1

I like it - particularly the 3000 RPM redline v. 5800 RPM - full disclosure, all my time is behind Lycoming and Continental engines with redlines around 2,500-2,600 RPM. Looks pretty narrow - so, as uofime-2 suggests, an aircraft designed around it could have a pretty narrow, aerodynamic nose?

"bhtooefr" (bhtooefr)

"bhtooefr" (bhtooefr)

04/24/2017 at 13:19, STARS: 2

Iíd say so - I mean, the Rotax 912 is less than half the displacement, and planes with that are where this is intended to go.

Iím not a pilot, but holding an engine at, oh, 5000 RPM in cruise just doesnít sound like itís a good idea, even if lots of people fly Rotax 912s without an issue.

"WilliamsSW" (williamssw)

"WilliamsSW" (williamssw)

04/24/2017 at 17:42, STARS: 0

I looked, and as far as I can tell, recommended TBO is 1500 hours, vs. 2000 for a Lycoming IO360. So, shorter, I guess (not that those numbers necessarily tell you whether or not either engine can actually go that long).

"pip bip - choose Corrour" (hhgttg69)

"pip bip - choose Corrour" (hhgttg69)

04/25/2017 at 07:00, STARS: 0

anyone make a flat-2?

"bhtooefr" (bhtooefr)

"bhtooefr" (bhtooefr)

04/25/2017 at 07:56, STARS: 0

For aviation engines, thereís the HKS 700 family (yes, itís the same HKS thatís a Japanese car tuner), and I think thereís still some† janky as fuck ďhalf-VWĒ engine designs floating around out there, which are exactly what they sound like they are, half of a VW engine.

And then for other applications (motorcycles, really), BMW is legendary for flat-twins, and Ural and Dnepr are still around making designs derived from pre-war BMWs.

"bhtooefr" (bhtooefr)

"bhtooefr" (bhtooefr)

04/25/2017 at 07:58, STARS: 1

One thing is, this is a new engine, and they plan to extend TBO to 2000 hours once they know more about how these engines behave in the field.

I mean, even the Rotax 912 family has a 2000 hour TBO nowadays...

"WilliamsSW" (williamssw)

"WilliamsSW" (williamssw)

04/25/2017 at 12:33, STARS: 0

Sorry - I was referring to the Rotax when I quoted the 1500 hours - but I think that actually applies to older 912's, and the newer ones are at 2000 - the same as an IO360. With this engine, it ought to be a matter of building a reliable service history to extend it.

"mr.choppers" (mr-choppers)

"mr.choppers" (mr-choppers)

05/07/2017 at 01:55, STARS: 0

Brazilís Gurgel built a half-VW (792cc) in sort-of semi-official factory conditions, called the ďEnertronĒ. To make things even weirder, it was water-cooled.