by "HammerheadFistpunch" (hammerheadfistpunch)

by "HammerheadFistpunch" (hammerheadfistpunch)

Published 04/18/2017 at 23:01

by "HammerheadFistpunch" (hammerheadfistpunch)

by "HammerheadFistpunch" (hammerheadfistpunch)

Published 04/18/2017 at 23:01

Tags: welding

STARS: 5

!!! UNKNOWN CONTENT TYPE !!!

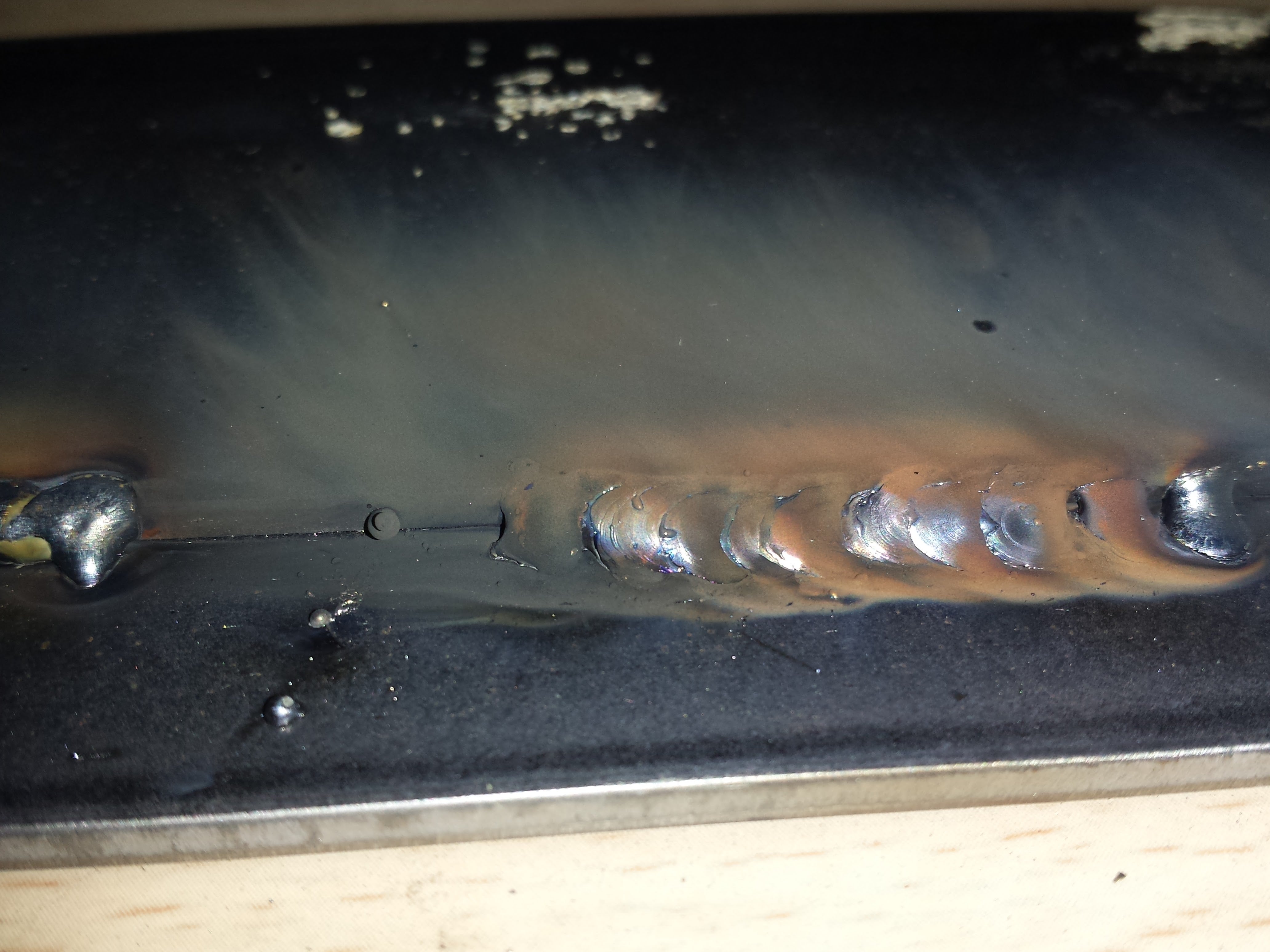

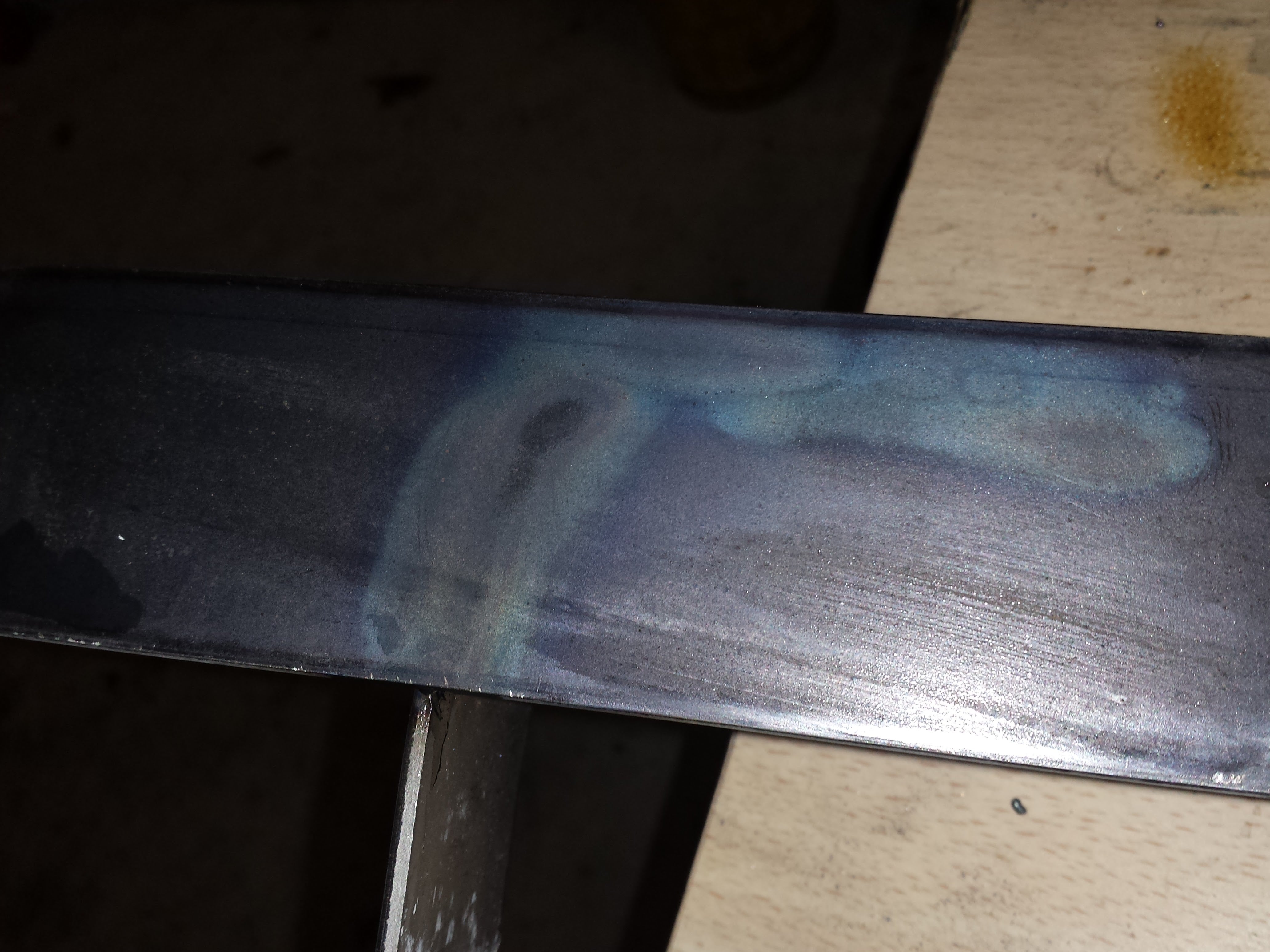

Please critique my welds. They stink, obviously, but am I getting penetration or just globbing on wire? Do my hinges look nice, nice free door hinges.

"Flynorcal: pilot, offshore sailor, car racer and panty thief" (flynorcal)

"Flynorcal: pilot, offshore sailor, car racer and panty thief" (flynorcal)

04/18/2017 at 23:05, STARS: 7

I, uh, appreciate the offer and the low, low pricing. Very kind of you. I really do appreciate the offer.

However Iím still gonna get my roll cage from the other guy. Sorry man.

"Arch Duke Maxyenko, Shit Talk Extraordinaire" (arch-duke-maxyenko)

"Arch Duke Maxyenko, Shit Talk Extraordinaire" (arch-duke-maxyenko)

04/18/2017 at 23:08, STARS: 4

"Highlander-Datsuns are Forever" (jamesbowland)

"Highlander-Datsuns are Forever" (jamesbowland)

04/18/2017 at 23:10, STARS: 1

Most of the welds look a bit cold. So I think in that case you move slower with a lower wire feed speed? Otherwise better than anything Iíve ever done. I tried it once and burned a hole in the metal. Put the welder down and left it to my wife who is a trained welder.

"Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)" (bman76-4)

"Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)" (bman76-4)

04/18/2017 at 23:12, STARS: 1

Well... since those hinges may be brass, brazing wouldíve worked better. Not bad for a first shot though, Miller has a great app for welding settings. Itís not difficult, it just takes practice.

"Alfalfa" (alfalfa-romeo)

"Alfalfa" (alfalfa-romeo)

04/18/2017 at 23:14, STARS: 2

Some look like theyíre getting some penetration, others not. My main critique would be to play with the angle of your wire to your work,to get equal amounts of bead on each of the 2 surfaces. Also pry some of those pieces apart and youíll get a better feel for how you did.

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

04/18/2017 at 23:16, STARS: 0

nah those hinges are just painted steel, I ground off the paint for them. Thanks though, I feel okay about them. Not pretty but I banged on the vertical bits with a hammer and could get them to move.

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

04/18/2017 at 23:18, STARS: 0

yeah, I think thats going to be the tricky bit, trying to learn to see with the welding helmet and keep the pool where I want it.

"Alfalfa" (alfalfa-romeo)

"Alfalfa" (alfalfa-romeo)

04/18/2017 at 23:22, STARS: 2

Yeah that takes some getting used to. An auto-darkening hood helps, if you arenít already using one.

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

04/18/2017 at 23:22, STARS: 0

I am but its HF....sooo....

"vicali" (vicali)

"vicali" (vicali)

04/18/2017 at 23:27, STARS: 1

Better than JB!

"Alfalfa" (alfalfa-romeo)

"Alfalfa" (alfalfa-romeo)

04/18/2017 at 23:32, STARS: 0

Haha so is mine, but itís not so bad.

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

04/18/2017 at 23:41, STARS: 1

Yeah, that guy sucks at welding!

"jkm7680" (jkm7680)

"jkm7680" (jkm7680)

04/18/2017 at 23:47, STARS: 1

Fuck yeah it helps. Feel like Helen Keller whenever I weld without one.

"TheTurbochargedSquirrel" (thatsquirrel)

"TheTurbochargedSquirrel" (thatsquirrel)

04/18/2017 at 23:49, STARS: 0

Looks better than the boogers I lay down.

"sn4cktimes" (snacktimes)

"sn4cktimes" (snacktimes)

04/18/2017 at 23:50, STARS: 0

Straight up welding with an older school lid isnít the worst. But new autos are SO much better for tacking while doing fitup.

"sn4cktimes" (snacktimes)

"sn4cktimes" (snacktimes)

04/18/2017 at 23:51, STARS: 0

Welder wife... hot stuff!

(Couldnít help myself)

"XJDano" (xjdano)

"XJDano" (xjdano)

04/18/2017 at 23:53, STARS: 0

Here is one of the ones I was getting paid to do. Came out alright...

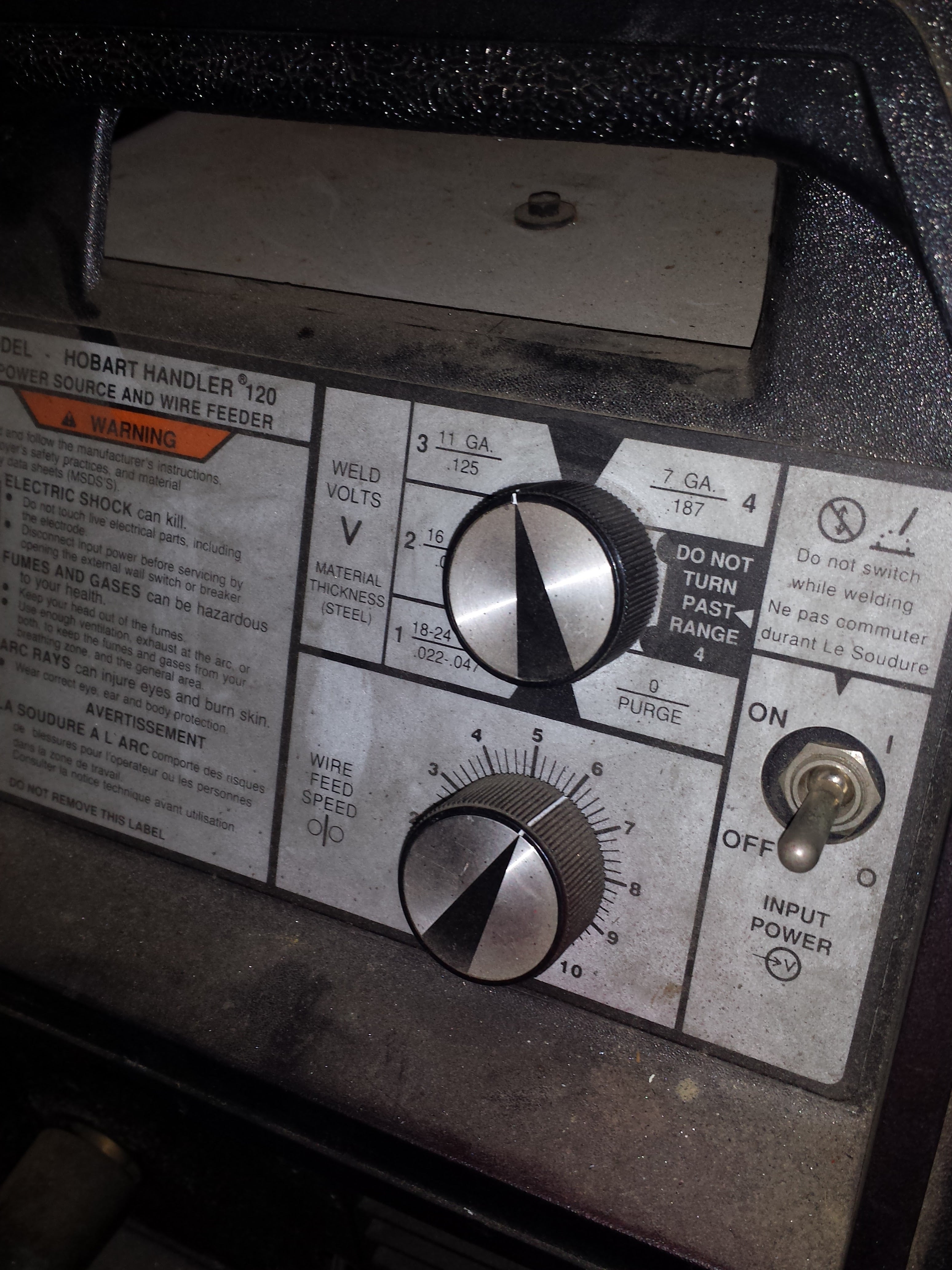

I even need more practice. The inside of my Hobart 135 has a handy chart for wire, speed, and steel thickness.

"AMGtech - now with more recalls!" (amgtech)

"AMGtech - now with more recalls!" (amgtech)

04/18/2017 at 23:57, STARS: 1

Penetration level: just the tip.

Needs more heat. Or conversely, less wire and slow down.

Not bad at all for first attempts. Iíve seen much much worse from people whoíve got much much more experience. The right half if the weld in pic #9 looks pretty decent. See how the weld flows into both substrates as opposed to sitting on top of them?

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

04/19/2017 at 00:02, STARS: 0

Yeah, Cold makes sense now that its been pointed out, I dropped the wire speed down but I didnít move slow enough and it just popped. I will try a little slower next time around.

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

04/19/2017 at 00:02, STARS: 0

yeah I used the chart for mine. Close, but I think i need to slow down.

"AMGtech - now with more recalls!" (amgtech)

"AMGtech - now with more recalls!" (amgtech)

04/19/2017 at 00:09, STARS: 0

Slowing things down might even make it easier for you to pay attention to your distance, angle, and the puddle. I think youíll pick it up pretty quickly though.

"sn4cktimes" (snacktimes)

"sn4cktimes" (snacktimes)

04/19/2017 at 00:18, STARS: 4

I think your settings are okay as thereís a few nice sections here and there. A few tips to make it all nice: with MIG (GMAW) the technically correct way to move you the gun is backwards/dragging it. But you will get a much nicer and flatter weld with more tapered edges if you push/go forward. So do that. Always. Aim right at the seam of the two parts. Keep a steady distance from the tip to the weld zone. Going up and down makes your voltage / amperage fluctuate which affects the weld quite a bit. A tight fitup also equals a better weld. An extra minute of prep might mean not grinding out and redoing a weld.

The gun has two general angles to try and hold steady while you work. One is the angle of the gun to the joint. You want it to be ďhalf the included joint angleĒ as a rule of thumb (thin gauge is better to aim more down than sideways). So if you have a 90 degree corner the default is 45 degrees. But like I said, flatter for thin stuff. The other angle to work on is how much your gun is tilted forward or back. You should generally have it tilted back towards your wrist at 5 - 10 degrees which is pretty much the angle of the bend it already has. Hold the gun parallel to the surface and however much tilt the head has just go with that for a bit. Keep in mind you can swivel/twist the gun around however you want in relation to travel, but as long as the head maintains those two factors itíll work. Thatíll make more sense as you weld more and have to attack stuff in awkward locations.

Then you just have to learn to move at a steady pace, with a steady tip-to-work distance while keeping your angles steady. Consistency is key. I canít stress that enough. Make it muscle memory with a good fitup and youíll crank out really great MIG welds. The sections of weld where both your top and bottom edges gently taper into the material are what you want everywhere. The parts that are really ďrolledĒ probably have very poor penetration. Itíll have a little in the ďcornerĒ and the rest is just sitting on the plate. Maybe fused to it, but not melted together fully. Just keep practicing, youíre already pretty close. Better than a lot of hobby welders Iíve witnessed.

If you want more info, Miller Welders used to have a VERY comprehensive information section with diagrams and videos. Not sure if they still do. But it was pretty relevant from learning hobbyist to professional levels for MIG, stick, and TIG.

Hope that helps a bit.

"atfsgeoff" (atfsgeoff)

"atfsgeoff" (atfsgeoff)

04/19/2017 at 00:53, STARS: 1

Bigger the gob, the better the job!

ďA grinder and paint, makes me the welder I ainítĒ

"Frank Grimes" (FrankGrimes)

"Frank Grimes" (FrankGrimes)

04/19/2017 at 01:39, STARS: 1

You welded! thats awesome doesnít it feel awesome!

get comfortable seriously take the time to get comfy and hold the torch/gun/shift/handle thing with two hands try practicing to see what works better for you pushing or pulling. try moving the arc back and forth across the two pieces being welded.

also watch all of these.

http://www.weldingtipsandtricks.com/mig-welding-videos.html

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

04/19/2017 at 07:36, STARS: 2

I am on my 3rd cup of coffee, so I could be drunk, but to me this one looks decent:

Itís a little messy, but it looks like you got both pieces there nice and welded.

I have no idea how to weld. My welder is still in the box in garage waiting for warmer weather before i start playing. Wife is just shaking her head.

"You can tell a Finn but you can't tell him much" (youcantellafinn)

"You can tell a Finn but you can't tell him much" (youcantellafinn)

04/19/2017 at 09:00, STARS: 0

For a first try those are decent welds. Try using a little less stickout, that goes a long way towards making a nice weld. For the small diameter wire youíre using (looks like 0.023" or maybe 0.030") you should have about 3/8" of wire between the contact tip and the work piece when youíre welding. Since the tip is recessed a little into the nozzle you probably want the nozzle just off the workpiece for the proper stickout.

The other thing to try for lap welds like that is ďwhippingĒ the weld. Instead of weaving back and forth between the two workpieces weld right in the bottom of the joint, but whipping the wire back and forth along the length of the joint. By whipping I mean travel say 1/2" down the joint, then back up over about 1/4" of the weld. Itís kind of a two steps forward one step back thing as youíre welding. When you do this you should still be using a pretty low travel speed.

It looks like youíve got a good handle on the basics. Basically at this point it comes down to fine tuning your settings and technique. Experiment with different settings, techniques and just burn more wire to get better.

Here is a good video I stumbled on that shows how to set wire speed and voltage.

!!! UNKNOWN CONTENT TYPE !!!