by "BaconSandwich is tasty." (baconsandwich)

by "BaconSandwich is tasty." (baconsandwich)

Published 03/31/2017 at 11:54

by "BaconSandwich is tasty." (baconsandwich)

by "BaconSandwich is tasty." (baconsandwich)

Published 03/31/2017 at 11:54

No Tags

STARS: 0

Tanner Faust posted a picture on Twitter this morning of a few Polaris side-by-side vehicles. This got me thinking...

Looking closely at the roll cage, they look like they are constructed of bent tubing. Assuming itís steel tubing, does putting a bend in it like that weaken it? Or does it depend more on how the actual tubing is bent? Iím certain that someone like Polaris knows what they are doing, but I am curious...

I know Iíve seen two different styles of bends - one with a constant radius and one where you can see itís been more pinched over than anything. Does the style of bend have an effect on overall strength?

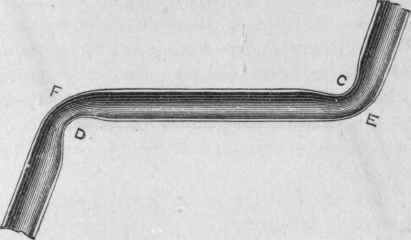

Example of a bend that has a more constant radius:

Example of a pipe thatís bent that doesnít have a constant radius:

"For Sweden" (rallybeetle)

"For Sweden" (rallybeetle)

03/31/2017 at 11:59, STARS: 4

Bending is plastic deformation and reducing the shell thickness, so it will reduce strength.

"benjrblant" (benjblant)

"benjrblant" (benjblant)

03/31/2017 at 12:04, STARS: 0

Short answer: Yes, somewhat. The sharper the bend and more deformation, the weaker the tube may become.

Highly likely that Polaris and its engineers accounted for this through designing or testing of the roll cages.

"CalzoneGolem" (calzonegolem)

"CalzoneGolem" (calzonegolem)

03/31/2017 at 12:06, STARS: 0

In other words. Yes. Yes it does.

"ShrimpHappens, nťe WJalopy" (bakeshake)

"ShrimpHappens, nťe WJalopy" (bakeshake)

03/31/2017 at 12:06, STARS: 0

Also consider that the alternative construction method would be some sort of butt-splicing, which would take longer and cost more to build and look bad.

"For Sweden" (rallybeetle)

"For Sweden" (rallybeetle)

03/31/2017 at 12:08, STARS: 0

In other words, strength will be reduced.

"CobraJoe" (cobrajoe)

"CobraJoe" (cobrajoe)

03/31/2017 at 12:09, STARS: 1

But is bending stronger or weaker than a welded corner?

Iím sure it depends highly on the radius of the bend and the shape of the tubing and the quality of the weld, but Iíd bet a large radius bent corner would resist spreading better than a 90 degree welded corner.

"For Sweden" (rallybeetle)

"For Sweden" (rallybeetle)

03/31/2017 at 12:10, STARS: 1

It might not be stronger, but the results are far more consistent. Welding has too many variables.

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

"Future next gen S2000 owner" (future-next-gen-s2000-owner)

03/31/2017 at 12:11, STARS: 0

Technically... No, but for the way most people understand strength, yes.

Even after plastic deformation the metal will slightly increase itís yield strength after deformation due to the stress/strain curve shifting to the right. However the reduced area means that it will fail at a lower force. It is all about stress, pounds of force/area. You gain higher psi before yielding but lower area reduces the force necessary for metal to yield.

"benjrblant" (benjblant)

"benjrblant" (benjblant)

03/31/2017 at 12:12, STARS: 0

And is very expensive/time consuming in a process where the goal is to crank out lots of parts for cheap.

"CobraJoe" (cobrajoe)

"CobraJoe" (cobrajoe)

03/31/2017 at 12:14, STARS: 1

True that.

Iíve been designing my own tube frame vehicle, and Iím trying to stick to bent tubing wherever possible, mostly because Iím not 100% in my welding skills.

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

03/31/2017 at 12:20, STARS: 3

Yes, mandrel-bent (even/ non-collapsed) is very much stronger than crushed. Also, the larger the radius, the harder to make it buckle end to end... mostly. Although, a tighter bend will work-harden the piece more, which can make it stiffer, which can make it stronger in other axes as part of an overall structure.

Also, a bent corner has much lower stress concentration than an unbraced welded corner, even disregarding whether the metal is weakened by the welding process. Which it is.

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

03/31/2017 at 12:21, STARS: 0

Welding even under the best conditions tends to leave stress concentrators, tight radii and whatnot, considering the way you make a ďbendĒ from cut and welded sections.

It all comes down to geometry. Someone who is good a building/designing cages will consider load paths and plan their routes accordingly.

"Matt Brown" (superfastmatt)

"Matt Brown" (superfastmatt)

03/31/2017 at 12:22, STARS: 2

The material is no weaker, but since the outside has been stretched, it is thinner, so the whole structure will handle lower loads. As far as welding, youíll usually have some heat treat on a steel or aluminum that would go away after welding. If you weld and then re-heat treat the whole assembly, you still have the full thickness of material but it would be weaker simply because of the geometry: a welded angle will have a higher stress concentration because of the abrupt change in geometry, so it will actually be weaker.

So the answer is: kind of. This is why you avoid rules of thumb and analyze entire structures.

"Bandit - destroyed his car" (notbandit)

"Bandit - destroyed his car" (notbandit)

03/31/2017 at 12:41, STARS: 0

From a materials stand point, a bent tube would actually be stronger than an unbent tube. Bending is a form of cold working which hardens the steel, at the same time it makes it more brittle. And Iíd trust a bent tube over a welded one as the heat from welding (if the welding was done poorly) could actually soften and weaken the metal unless after the fact heat treatment was completed.

"tromoly" (tromoly)

"tromoly" (tromoly)

03/31/2017 at 12:43, STARS: 1

Proper triangulation is more important, that Polaris cage is decidedly lacking support for that front halo.

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

03/31/2017 at 12:44, STARS: 1

Its all geometry. Youíve got to be careful about what you mean when you say strength. How is it being loaded?

It all ends up being solid mechanics.

Metals fail tension.

High enough compression loading causes buckling, which means the member bends.

Bending loads will have part of the member to be in tension and the other in compression..

When you construct a cage you think about how it will be loaded and try to have a member that will be in compression to handle that load. that is often not possible so you link members together to eliminate bending.†

"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

03/31/2017 at 14:15, STARS: 0

Excellent question! And some excellent responses here.

"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

03/31/2017 at 14:15, STARS: 0

Now youíve got me curious. What sort of vehicle are you designing?

"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

03/31/2017 at 14:17, STARS: 0

I know itís a pretty vague question, but how would a bent corner compare to a welded corner that has a gusset?

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

03/31/2017 at 14:22, STARS: 0

Depends on the gusset, depends on the wall thickness, depends on weld-affected-area, material in use, etc. etc. etc. Best of all worlds might be a gusseted bent corner with a non-affective attaching method like low-temp brazing.

"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

03/31/2017 at 14:41, STARS: 0

When you say front halo, you mean the area around the side, where the passenger would enter/exit?

"CobraJoe" (cobrajoe)

"CobraJoe" (cobrajoe)

03/31/2017 at 15:06, STARS: 1

I have been working on a sort of street buggy type locost for a few years now, I already have the parts from a donor car and a pretty good design figured out, Iím just tweaking it in CAD to allow for a larger engine than I was originally planning.

The result should be a 2 seat mid engined open car with a curb weight of roughly 1200 pounds (probably a bit more) powered by a 140hp B18B1 from an Acura Integra. That should make it a ton of fun in a half ton package.

"tromoly" (tromoly)

"tromoly" (tromoly)

03/31/2017 at 15:20, STARS: 1

I used the wrong term, meant front hoop instead of halo. I was referring to the bend should be better supported like in the below picture, but for a stock utv the cage really should only be necessary for low-speed tip-overs, so it doesnít need to be as beefy (not to mention the support makes it harder to enter and exit the vehicle).

"TheTurbochargedSquirrel" (thatsquirrel)

"TheTurbochargedSquirrel" (thatsquirrel)

03/31/2017 at 17:33, STARS: 0

When done properly so the tube isnít crushed it is just as strong as unbent tube. If you crush it though it creates a major weak point.