by "TheHondaBro" (wwaveform)

by "TheHondaBro" (wwaveform)

Published 02/10/2017 at 15:33

by "TheHondaBro" (wwaveform)

by "TheHondaBro" (wwaveform)

Published 02/10/2017 at 15:33

No Tags

STARS: 1

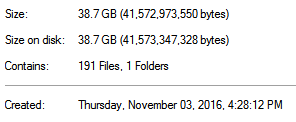

But dat folder size.

"Cherry_man1" (Cherry_man1)

"Cherry_man1" (Cherry_man1)

02/10/2017 at 15:37, STARS: 1

Fak dat size

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

02/10/2017 at 15:44, STARS: 0

Every sheet metal part here at my place of work is covered with under 4 gigs. Lulz AutoCAD 2d. Even counting the Inventor stuff, itís not all that extensive. Last time I was processing such abominably huge files was when I was doing FEA on stuff in NX.

"EngineerWithTools" (engineerwithtools)

"EngineerWithTools" (engineerwithtools)

02/10/2017 at 15:45, STARS: 0

...and I donít know about you, but I prefer to keep active models on a way-more-expensive-per-GB SSD for faster loads.

(Yes, I back up.)

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

02/10/2017 at 15:45, STARS: 0

you should see some of my video project files. 39 gb could be as few as 3 minutes.

"TheHondaBro" (wwaveform)

"TheHondaBro" (wwaveform)

02/10/2017 at 15:49, STARS: 0

I think my next PC upgrade will be an SSD. I got a 2TB HDD when I built it two years ago because I got a good deal, but I do like faster boot times.

"If only EssExTee could be so grossly incandescent" (essextee)

"If only EssExTee could be so grossly incandescent" (essextee)

02/10/2017 at 16:00, STARS: 0

Do eeeeeet. Best decision I ever did make.

"EngineerWithTools" (engineerwithtools)

"EngineerWithTools" (engineerwithtools)

02/10/2017 at 21:36, STARS: 0

Thread jack alert...

Doing sheet metal with 2d Acad still? Laser-and-form is such a common and efficient manufacturing process, and parametric 3D makes its design process just as efficient. I often push NX (or specifically my engineering services with NX) on metal bending alone.

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

02/13/2017 at 09:06, STARS: 0

The basics of it are these: we have enough volume to have a brake, a shear, and two turret punches busy for a lot of the day, but not quite enough volume to where weíve ever bothered to set up for laser. As to the parts themselves, nothing weíre making has any kind of stamping or anything exotic, and about half of it is worked up in Inventor, then generated as a 2d parts drawing. I personally have a series of hacks using 3d solids to size the parts, which enables me to work very fast, though - in theory - doing it ďproperlyĒ would be better.

How did I come to be working with 3d solids AutoCAD if I had Inventor available? If youíre familiar with Inventor, itís designed to inconvenience any business with more than one version of Inventor and anyone trying to manage or alter anyone elseís project. There is so much hassle involved for me to try to open or work with any of the Inventor material that it usually makes more sense for me to not even try - and anything I canít easily replicate, I just request the Inventor guy to export in 3d .dwg.

I would like to be working in NX. That is not going to happen, so ACAD 3d->2d it is. I would like to be working in SolidWorks. Apart from me setting up my own drafting station at my house one piece at a time and saving for a license, thatís not happening at my place of work either.

"EngineerWithTools" (engineerwithtools)

"EngineerWithTools" (engineerwithtools)

02/13/2017 at 10:04, STARS: 0

Lasers are great (freakin lasers, man!), but unless youíre in a high-profit niche, you have to have enough volume to run them 40 hours / week for the $$ to work out.

Youíve just helped me with something - Iíve recently talked to a local fab shop about engineering work, or even a position. They have one or two people on Inventor but seemed... unenthusiastic?... about the performance they were getting, particularly around reusing designs. Now I have an idea of why - their business requires a lot of engineering info passed back and forth with customers.

In addition to NX, I am a long time 2D autocad user (yikes, 22 years), at least for system layouts, because a lot of my work has interfaced with civil contractors, but I havenít ever used Inventor.

Like lasers, NX can be a stretch to justify unless youíre using the vertical market add-ons, doing advanced machining, or itís mandated by one of your customers. I finally gave up trying to justify it and just told myself that Iím paying 2x for software because of personal preference.

BUT! SolidEdge is relatively cheap, even compared to ACAD - and you can pay by the month too - and has some very handy features for working with legacy dumb solids.

Anyway, thanks for the info!

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

02/13/2017 at 10:41, STARS: 0

The train wreck part of working with Inventor is that every single time you work on something, it has to be handled in its own project folder. Every time you open something new, you have to convince it to work within the folder where all its parts are and tell it where all the parts outside the project folder are, and if you were not the last person to work on the project you may have to reassign all the part references. ďYes, Inventor, that part is in *this* folderĒ. ďYes, Inventor, I do want to change to a new project folder - DO NOT TRY TO MAKE THIS PART OF THE LAST PROJECT WORKED ON, YOU IDIOTĒ.

This is compounded by the fact that every single time you open something, it updates that part to the version of Inventor you opened it with, and there donít seem to be good ways to force it to stay backward-compatible. Even with the same version of Inventor, the build seems to matter. So, in other words, having an older edition of Inventor on one or more machines or even a machine thatís not rigorously updated means no ability to open the work of the guy with the newest software.

I can open an assembly that was created last year, but because my coworker has so much as opened a pipe fitting used on that part within the past six months, my older Inventor says ďI say, where is that fitting part? I donít recognize anything! Mother, mother, Iím blind!Ē. I then have to proceed without it, because idiocy.

Thereís probably some way to alter that, but my coworker has never found it. Related to the above, Inventorís project/project folder handling has never given me the impression that any kind of assembly file is even close to portable. Which sucks. Iíd like it to embed/store parts and not lose its mind, but Iím not good at making it do that, and it insists that the newest version of the piece must be used.

In other words, to use Inventor needs either a budget to keep everybody up to the absolute latest build, or only one guy handling Inventor, and all Inventor files staying within the building. I donít know how much of the impossibility of working with it is due to my coworkerís convenience settings, but in a perfect world it wouldnít matter.

Let me offer some more background on what I do: itís not only sheet metal parts for production as above, itís also drawings of conditioning units (temp *and* Rh, high precision) and drawings of insulated rooms. My side of things (more so than the Inventor guy, whoís usually on whole new-unit designs) very often involves taking customer AutoCAD and putting our things in it. So, I design a part, I put it on a conditioner, I put that conditioner on a room, and I put customer AutoCAD around it. You can see how keeping everything in 2d ACAD to a degree is a huge plus.

I have used Inventor *some*, but I have found that it is far simpler for me to go berserk with simple plate extrusions and pline traces of things than to try and operate somehow in parallel with other people. I am not yet very good at Inventor because working with it on anything I need it for is masochism in my situation. At one time, I was pretty proficient at NX, but Iím very rusty.

I have used SolidEdge, but itís been a long time. Like, 2005-a-long-time. Iíve mostly been looking at SolidWorks for career reasons more than just what Iíd like to use for my own purposes.